KHODIYAR INDUSTRIAL PRODUCTS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KHODIYAR INDUSTRIAL PRODUCTS

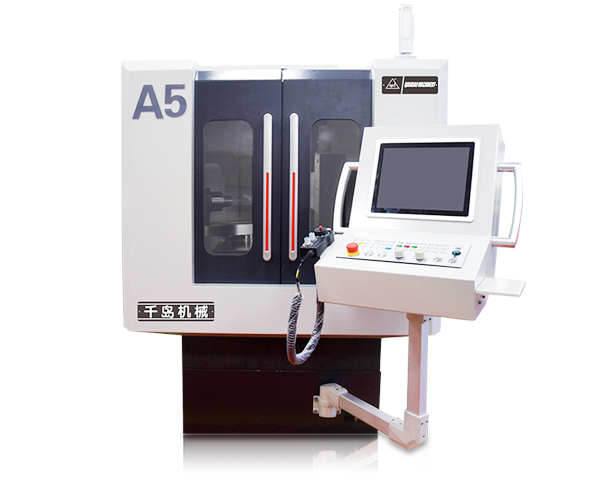

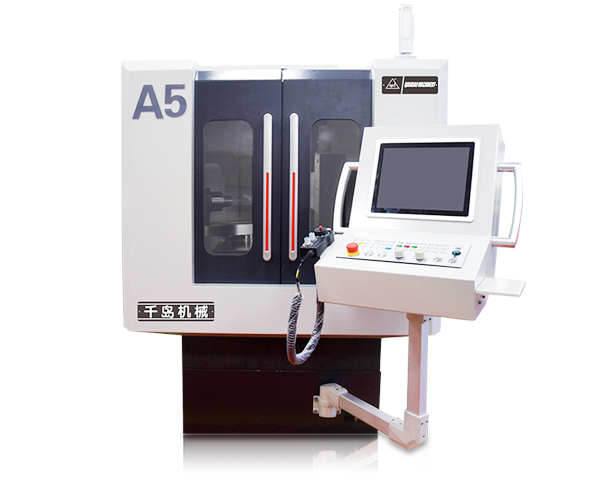

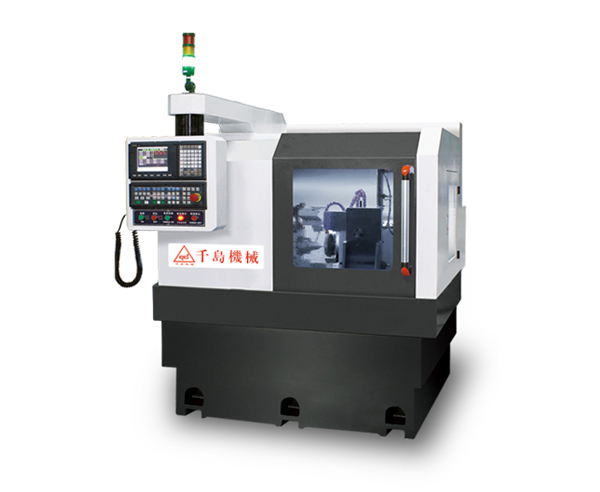

C.N.C Tool Grinding Machine

Description / Specification of C.N.C Tool Grinding Machine

We are involved in offering a wide range of C.N.C Tool Grinding Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of C.N.C Tool Grinding Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

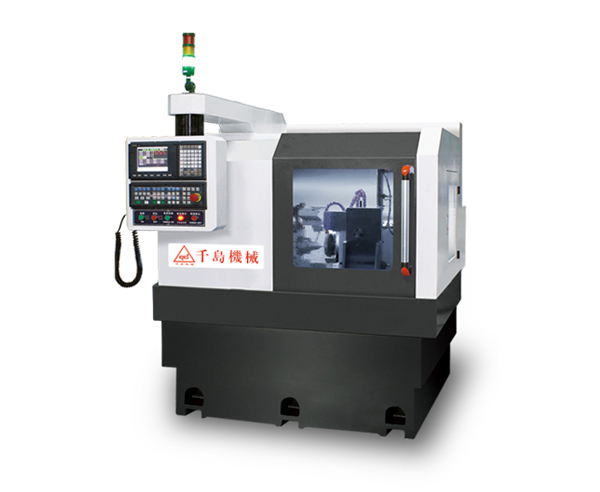

Cylindrical Grinding Machine

Low high precision collet type numerical control period of poor grinder ontology and nine components by senior meehanite cast iron FC30 moulds, the artificial normalizing heat treatment, natural aging treatment after more than six months.Processing components adopt YASDA, MITSUI SEIKI, TOSHIBA, ELB world-class equipment such as the clamping process at a time.Precision can reach micron grade, to ensure that the equipment foundation components and high precision. When the machine adopts Taiwan new generation or Japan mitsubishi CNC system, can be done directly through the program with a taper abrasive.Operating procedure is simple and convenient.Grinding out of good stability, workpiece precision compared with traditional

Centerless Grinding Machine

The machine is used for all kinds of cylinder parts grinding and grinding cone, forming the plunge-cut grinding of axially symmetrical parts.Suitable for the batch and mass production needs.

1. grinding wheel spindle bearings for five chip dynamic pressure sliding bearing, bearing capacity, high precision.

2. guide wheel spindle bearings for 1:30 integral sliding bearing, large carrying capacity, high precision.

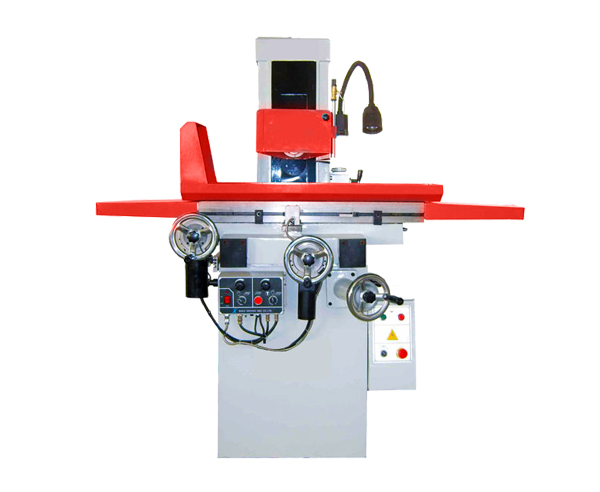

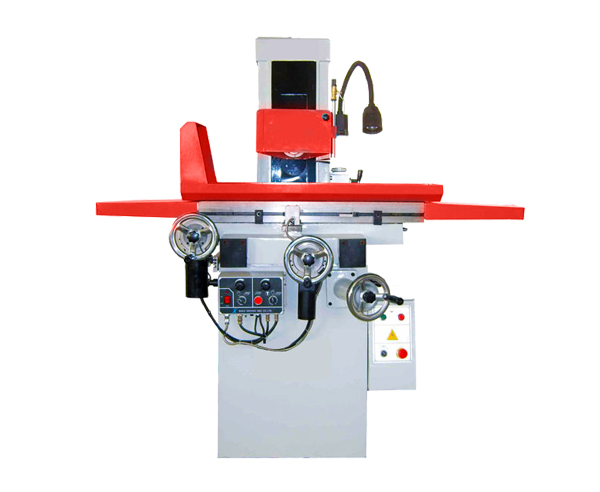

Surface Grinder Machine

Features:

1.Machine with compact structure,appearance,good rigidity,easy to operate.

2.Based on 618,820 surface grinder,we changed the it from manual operation into electric control.It significant improve work efficiency,reduce labor intensity,especially during grind high-volume workpieces,it significant improve part surface finish.

3.Adopted P4 level precision spindle bearings.

Chamfer Machine

1.GD-900D Multifunctional composite slide chamfering machine revolving speed is 8000 rpm,Suitable for all kinds of machinery and mould workpiece chamfering.

2.This machine adopts "slide" method, Can improve the work efficiency, and will not scratch the surface, especially suitable for grinding machine processed high roughness workpiece chamfering.

3.The panel adopts hard chromium plating, durable, anti rust.

Universal Tool Grinder

Features:

The machine workbench using high precision linear guide, the bed platform balance, operating and lighter.

Cooperate with various accessories can be grinding: forming tool, vertical milling cutter, R milling cutter, reamer, turning tool, R type lathe tool, gear hobbing cutter, drill, tap, burin, strong cutting tool, chamfering knives, paper cutting knives, cylindrical, flat groove, forming surface, etc.

End Mill Grinder

Feature

1. The machine is a portable type, can be fast grinding 2, 3, 4, 6 blade of general end milling, tungsten rod directly open bladeas well;

2. Rapid and precision grinding , easy operation;

3. Diamond grinding wheel, can complete all the process, accurate, long life, save the cost and improve efficiency.

Linear Cutter Grinder

Feature

This machine is mainly used for grinding all kinds of different angles of the straight edge knives, it is used for sharpen furniture, printing , textile and other industries different type tools , also can be used for high speed tool steel open ramp etc.machine is mainly composed with the main body,worktable ,slide motor ,grinding head, and electrical, the stucture of each section is compacted, machine can sharpen 4 blades knife at the same time . the grinding head feeds automatically in average speed that ensure the cutting tool exert it's unique advantages equally. it is the necessary grinding machine for the indus tries of furniture amking and straight blade making.

Saw Blade Grinder

Product Features

This machine is specially designed for hard alloy saw blade grinding blade design, adapt various hard alloy saw blade grinding; Equipped with adjustable type around the plate, can maximum limit hold saw blade tooth department or other mill; With positioning pins, can according to the size of the saw blade diameter and tooth, adjust to the best position; Skateboarding is horizontal rotation, can be keep the original of saw blade grinding blade Angle or the change; The worktable is equipped with rotary table, easy to adjust feed grinding blade Angle; Rotary table with a slider, axis, the limit screw, both convenient operation; And ensure that the radius of the edge to center of grinding, grinding head has a plus or minus 20 ° rotating mechanism, can meet the grinding helical blade serrate.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.