KILBURN CHEMICALS LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KILBURN CHEMICALS LTD.

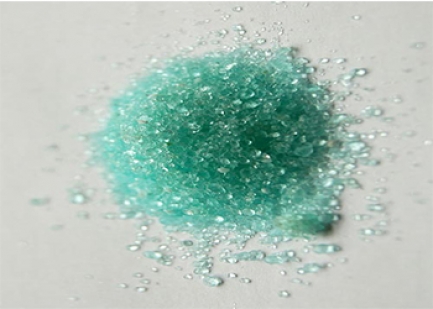

Ferrous Sulphate Hepthahydrate

Kilburn Chemicals Ltd is the major producer of copperas, with over a decade of experience supplying to various user industries.

Kilburn Chemicals produces Titanium Dioxide (Anatase) through sulphate process and copperas is produced as a bye-product after crystallization and separation from the process liquor.

[ferrous sulphate hepthahydrate]

Copperas is used as an additive in cement to minimize the risks of the harmful hexavalent chromium contained in cement. Kilburn Chemicals is able to supply copperas to cement manufacturers fulfilling the requirements of EU directive 76/769/EEC, 26th amendment. The directive demands the reduction of hexavalent chromium content to below 2 pm.

Copperas is also widely used as a coagulant in water treatment chemicals, and as a raw material for iron oxide pigments.

Ferrous Sulphate - Copperas Product Dry Product Drier

pH (5% of slurry) 3.10 (min) 3.10 (min)

Moisture (Percent by Mass) 0.50 (max) 0.40 (max)

Iron (Percent by Mass) 19.88 (min) 19.90 (min)

Purity as FSH (Percent by Mass) 98.70 (min) 98.80 (min)

Ferric Iron (Percent by Mass) 0.20 (max) 0.15 (max)

Free Acid (Percent by Mass) 0.30 (max) 0.25 (max)

COPPERAS - Advantages

Copperas is suggested for usage in the Cement Industry in order to reduce the hexavalent chromium content to below 2 ppm. To this effect, an EU directive has already come into force to protect workers during possible skin contact with hydrated cement.

Chromates can cause allergic dermatitis among workers coming into contact with the material. By adding copperas, the chromium is reduced to its trivalent, non-soluble form eliminating the harmful effects of chromium eczema.

Copperas is used as a coagulant in water treatment. Also it is used as a micro-nutrient via the fertilizer application in the Agriculture Industry.

How to use Copperas in Cement

Addition to grinding (Dose 0.3 - 0.6%) which gives uniform distribution. The addition is weight controlled.

Addition to grinding mill feed (Dose 0.5 - 1.00%). The addition is made separately or mixed with clinker or with other feed components.

Addition before packing (Dose ~ 0.5%) requires good or excellent mixing and is used in dry mortar and other cement preparation demands fine dust size particles of iron sulphate.

KILBURN COPPERAS is available

Dried Free flowing material

Dried crystals

Handling

Wear normal protection

Store in a dry covered place

Avoid rain or moist conditions

Avoid dusting

Avoid high temperatures, melts at 650C

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.