KHOSLA MACHINES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KHOSLA MACHINES P.LTD.

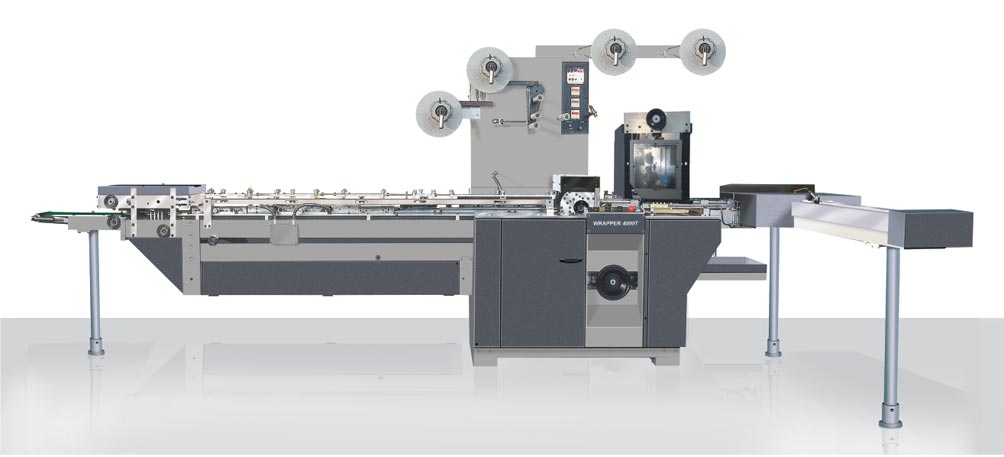

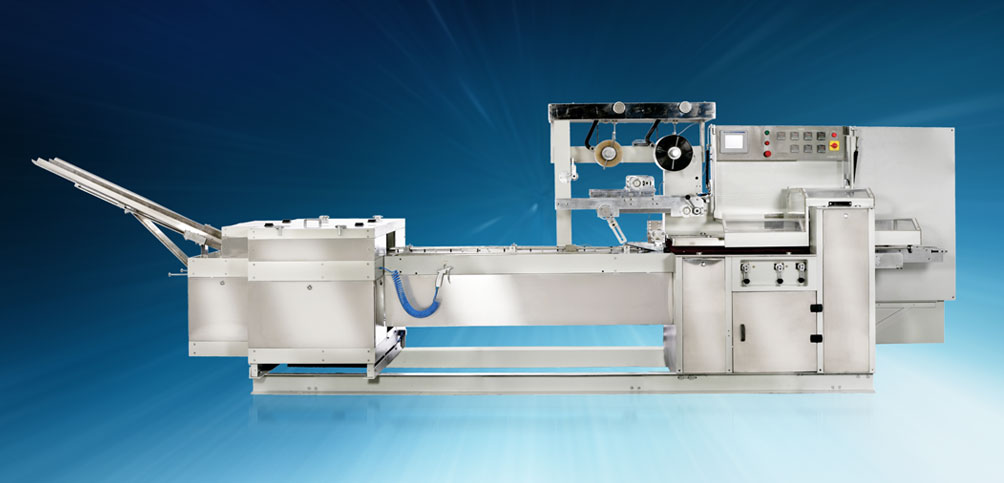

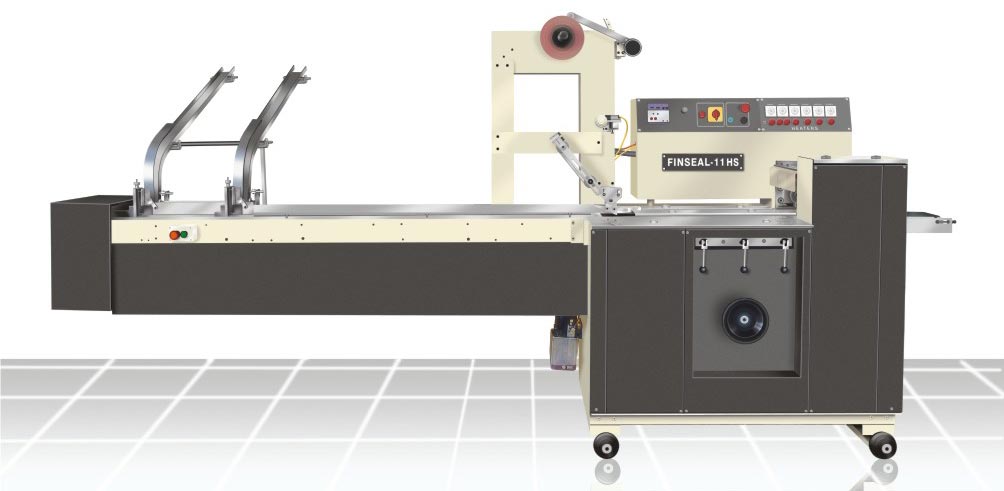

Horizontal Form Fill Seal Machine For Soap

PRINCPLE OF OPERATION:

Soaps are placed on flat belt conveyor, either by link up conveyor (not a part of the of the machine) or manually. These soaps are transferred to the infeed lug conveyor of the machine. Infeed conveyor then transfers soap into wrapping film that has been formed into a tube by means of forming folder. Bottom seal is made by three sets of rollers. Cross sealing and cutting knife separate the packed soaps. Heat sealable material like BOPP or laminates is used.

STANDARD FEATURES

All surfaces over which soaps are transported are made of stainless steel Flat belt conveyor infeed with Transfer Unit Long seal is formed by means of three pairs of rollers, axes of which can be tilted to get best results Torque slip clutch to prevent damage in case of accidental jams Low voltage heaters for safety Individual temperature controls for heaters Print registration unit for printed wrapper Heavy distortion-free cast structure

Highlights

» Specially designed for wrapping toilet soap (Regular and guest size),

» Laundry soap and detergent bars

» Link up of machine to plodder possible

» Individual packs or chain packs

» Two or more soaps can also be inserted in one pack (depending on size).

Options

» Date Printing unit

» Variable speed drive (AC frequency control)

» Castors for mobility of machine

MACHINE SPEED UPTO 120 PPM INFINITELY VARIABLE

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.