Alkaline Zinc Plating

Alkaline Zinc Plating

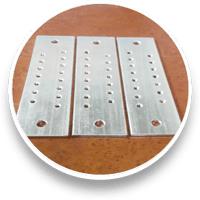

Alkaline Zinc Is decorative and functional cyanide-free zinc plating processes. They provide ductile coatings with high brightness and outstanding thickness distribution even on complex-shaped parts. The excellent throwing power allows to load more parts and to reach higher productivity.

27374.jpg)