JRMS ENGINEERING WORKS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JRMS ENGINEERING WORKS

Composite F. R. P. Vessel

Our filament wound fiber glass reinforced plastic pressure vessel is the material of choice for commercial and industrial water treatment system. The FRP vessel comprise of either a high grade corrosion resistant FRP or a poly ethylene liner (corrosion barrier) for all standard water treatment application including deionization and offers a wide chemical resistance, outstanding performance and durability in harsh chemical environment impact and weather resistant structural laminate perception molded threaded tank openings and supported with FRP support base(tripod/skirt) stand capable of bearing complete load.

A) FRP Vessel also available

1) Top / Top Bottom

2) Manhole : 400 mm/ 450 mm/ 500 mm

3) Handhole : 100 mm / 150 mm / 200 mm

4) Staner Plate : Available at 900mm Vessel

B) FRP Vertical Vessel Size Starting : 8x44 to 120x130

C) FRP Horizontal Vessel Size Starting : 900mm x 1800mm to 3500mm x 12000mm

F. R. P. Vertical Tanks

|

F. R. P. D. M. Water Storage Tank

|

F. R. P. Packaged Sewage Treatment Plant

|

F. R. P. Bio Toilet

Salient Features Of Our Bio Toilets

- Easy maintenance.

- Heat Resistance

- Eco-friendly

- 100% maintenance free

- 100% hazard free

- Compact design

- Easy to transport

- Chemical resistance

- Long lasting

- Corrosion resistance

- Water-proof

Benefits Of Using Our Bio Toilets

- Prevents untreated water and human wastes from groundwater contamination

- Comes with pre-fabricated shelter

- Eliminates the need for costly waste treatment

- Digests organic solids ecologically

- Offers a great alternative to dumping of sewage into lakes, rivers and fields in semi-rural and rural areas

Why Choose JRMS Engineering Works For Bio Toilet?

- We are renowned bio toilet manufacturers who prioritise customer satisfaction

- Durable bio toilets manufactured by a team of experienced professionals

- Each of our bio toilets meet the requirements of our clients

- Manufacturers with a wide range of high-quality bio toilets

- Bio toilets and FRP bio toilets available at reasonable prices

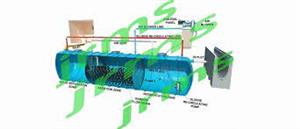

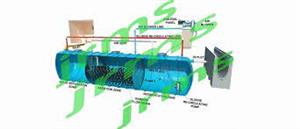

F. R. P. Sewage Treatment Plants

- hey make room for effective and economical sewage treatment.

- Products of the like help in reducing the Biological Oxygen Demand (BOD) of water.

- They help in extracting water from sewage and readying it for agricultural usage.

- Because of the FRP, the plants help in water treatment for a longer time.

- Whenever centralised municipal sewage treatment plants are not available, these decentralised plants can suffice the purpose of industrial wastewater treatment.

- They are a unique solution to minimise carbon footprint.

What Is The Working Principle Of These Units?

Filtralite media is used in the units to assist in the biological purification of sewage. The media help in the degradation of suspended components and removal of ammonia, arsenic, iron, and fluorides. It also encourages the growth of microbes that break down the organic contaminants. The FRP keeps the media from damaging the unit. The sections in the unit contain filtration membranes which help in cleaning the sewage and assisting in sedimentation. The materials which settle in each section, form the sludge, which is then pumped back to a septic tank. From here, the sludge is eventually removed.

Why Choose FRP Packaged Sewage Treatment Plant From Jess Industries – the Manufacturers In India?

- We are the FRP packaged sewage treatment plant manufacturer in India who have years of experience.

- Manufactured cutting-edge technology, these products are suitable for commercial and industrial level decentralised wastewater treatment.

- Our products are of compact design and require minimal space in your sewage treatment unit.

- They can be customised as per requirements and consume less time for installation on site.

- The products are completely made from FRP, lightweight, durable, leak-proof, heavy duty, high performance, and corrosion resistant.

- They also provide ambient temperature insulation.

- They are an economical way of treating waste water.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.