J D JONES AND COMPANY P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to J D JONES AND COMPANY P LTD.

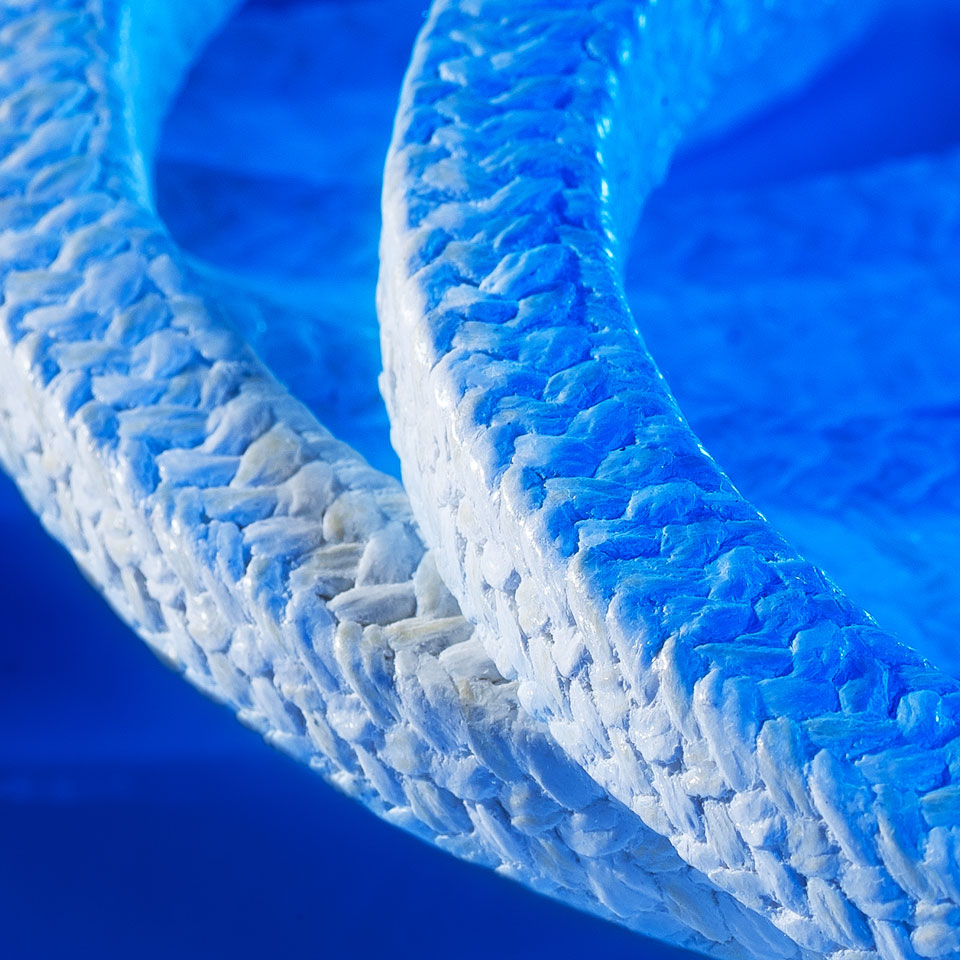

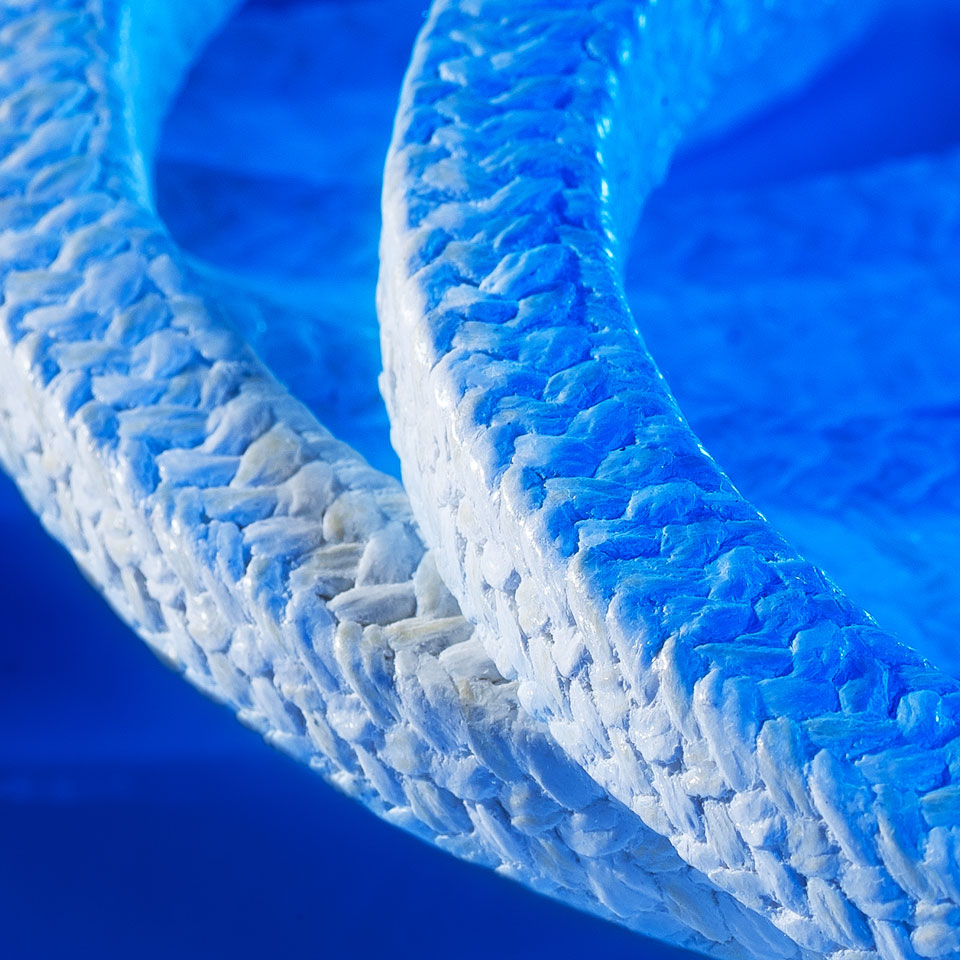

Acrylic With Spun Aramid Braided Packing

Synthetic fibre braided packing having cross braided of abrasion resistant aramid staple fibre impregnated with PTFE and break-in lubricant

A special purpose packing with abrasion resistance, thermal stability, flexibility and good chemical resistance

Thorough impregnation of PTFE provides trouble free start-up and low friction operation

A high density packing good for crystallising media

P.T.F.E. Graphited Braided Gland Packing

Multi-yarn packing made from pure PTFE fibre corners with expanded PTFE graphite fibres at the running surface in interlock braid

The expanded PTFE graphited fibres yarns at the base provide excellent chemical resistance, low co-efficient of friction and virtually eliminate shaft scoring

The pure PTFE fibre yarns at the corners provide superb extrusion, abrasion and pressure resistance, allowing the packing to be used at very high pressure conditions

P.T.F.E. Graphited Gland Packing

Expanded PTFE graphited gland packing encapsulated over aramid fibre on each yarn

A true multi-service packing

Excellent chemical resistance, heat dissipating, sliding velocity, low co-efficient of friction properties of PTFE graphite and abrasion, pressure resistance and mechanical strength of aramid

Each expanded PTFE graphite yarn is encapsulated over aramid filament yarn

A soft supple packing, non-abrasive in nature and gentle on the shaft

Glass Fibre Braided Packing

A high grade high "tex" glass fibre braided packing impregnated with PTFE and high viscosity special grade lubricant

A universal packing made from high quality glass fibre yarn impregnated with PTFE and lubricant

Very low co-efficient of friction, high thermal conductivity and sliding velocity, runs almost frictionless without any shaft wear

Excellent resistance to chemicals and hardening thereof

Copper Corner Braided Packing

A high grade unconventional braided packing made from acrylic fibre yarns with PTFE impregnation and break-in lubricant having copper wire on outer corners in interlock braid

Latest development for knife gate valve industry replacing conventional packing set of acrylic fibre or PTFE braided packing with copper wire braided anti-extrusion ring at top and bottom

The unique structure of the packing makes it ideal in terms of heavy duty corrosion and abrasion resistance for the toughest liquid slurry and dry material handling applications

Copper wire on the corners eliminates distortion under maximum differential pressure while an acrylic fibre PTFE impregnated face ensures tight sealing

Copper, being very soft and ductile, reduces wear and tear

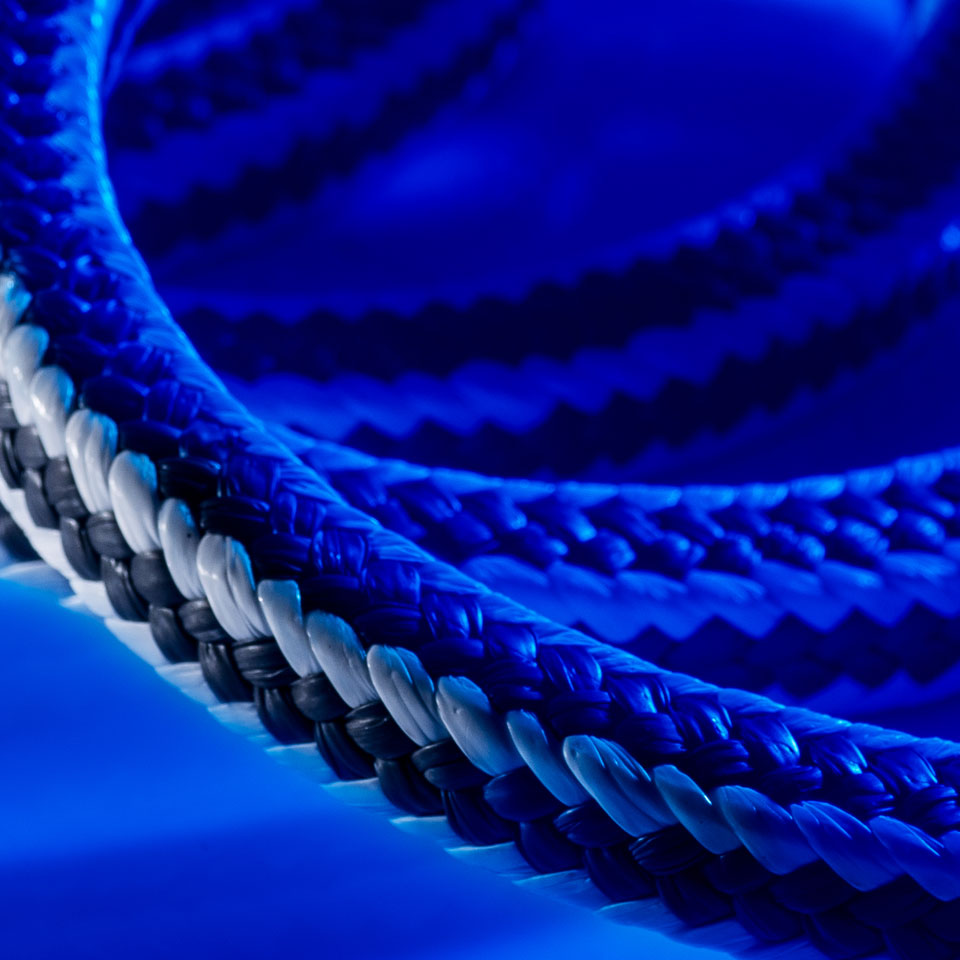

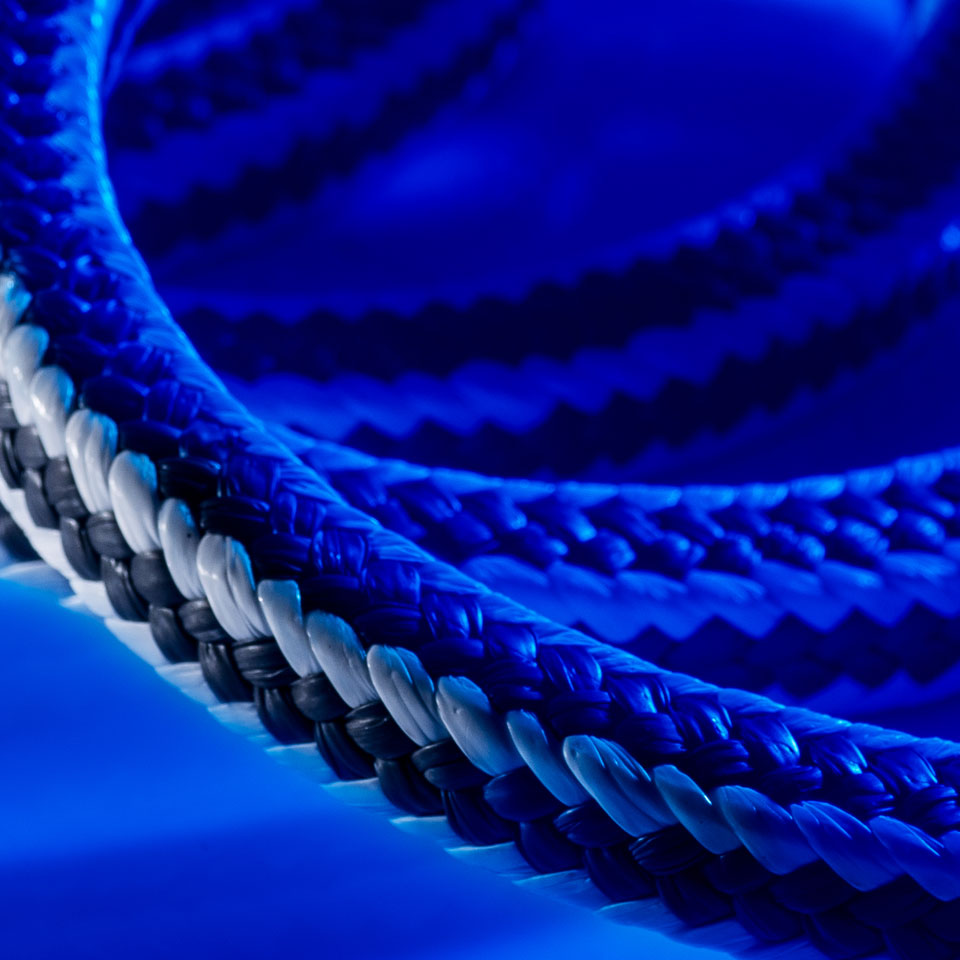

Multi Yarn Packing

Multi-yarn packing made from pure aramid fibres with corners of pure PTFE fibres at the running surface

The PTFE fibres yarns at the base provide excellent chemical resistance, low co-efficient of friction and virtually eliminate shaft scoring

The tough PTFE impregnated aramid fibre yarns at the corners provides superb extrusion, abrasion and pressure resistance, allowing the packing to be used at very high pressure conditions

Clean and non-toxic, can be used over a wide range of media including critical services that demand an extrusion resistant or reinforced packing

Cross Braided Packing

Cross braided packing made of pure PTFE yarn and aramid yarn

The PTFE fibres yarns provide excellent chemical resistance, low co-efficient of friction and virtually eliminate shaft scoring

The tough PTFE impregnated aramid fibre yarns are pressure resistance, allowing the packing to be used at very high speed with minimal shaft wear

Novoloid Fibre Packing

Novoloid fibre packing impregnated with PTFE and break-in lubricant in interlock braid

Pure novoloid fibres exhibit the strength of aramid and chemical resistance of PTFE/graphite

A multipurpose plant-wide packing for the pulp and paper industry

A thorough impregnation of PTFE provides low friction operations and a dense packing without any leak paths

A non-staining and non-abrasive packing—can be used for high speed applications

Insupac Mouldable Type Packing

Insupac mouldable type packing for scored sleeves

Extremely flexible and malleable ‘mouldable’ type packing that can conform to any shape in the stuffing box, filling all deformities, irregularities and scorings and cutting out all leak paths

Excellent chemical resistance, non-scoring and anti-frictional properties—can be used over a wide range of applications

Manufactured from self-lubricating materials with excellent heat dissipation properties

Provides optimum sealing effect in conjunction with braided gland packings

Can be used over a wide range of cross-sections of the stuffing box, eliminating the need to stock various sizes

Tank Lid Packing

Sealing of tank lids, inspection and cleaning covers on tankers carrying all known bulk liquid

Made by spiral wrapping of PTFE tape over a core of elastomer, jacketed with inert polypropylene yarn

Braided structure is spirally wrapped to provide an impermeable barrier to liquids

Final jacketing of polypropylene yarn gives complete protection to the packing and makes it abrasion resistant

The unique core construction enables the packing to be stitched together to form an endless seal, thus preventing the chance of any leakage at the joint

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.