JANAKSONS OVERSEAS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JANAKSONS OVERSEAS

Water Management Plants

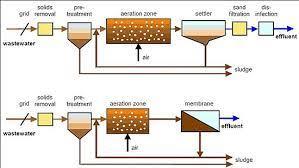

The solutions offered for wastewater depends on parameters such as the feed, COD, BOD, TSS, Colour, TDS etc and these parameters vary. Our design team has many years of experience in handling and treating BIOLOGICALLY the effluent generated from Textile, Tannery, Sewage, etc.

SCREENING

As the word suggests, this process is to screen the water from the coarse and medium-fine solids being discharged in the wastewater. It helps to avoid settling of this solid in the tanks and clogging of crucial and expensive equipment installed in the plant.

The screen section is placed normally at ground level before feeding the water to the effluent treatment plant. The screening equipment can operate both automatically or manually.

Types of screens: Rotary Drum, Brush Screen, Disc Screen, etc.

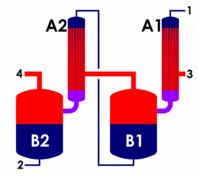

EQUALISATION

The equalization or homogenization process forms a very important part of the complete scheme of the ETP. The process house normally discharges different qualities of water with different flows. Hence it is important to mix the water well to ensure that an average quality of effluent is fed to the oxidation plant.

The mixing of water is done with the help of diffusers where the tanks are constructed in rectangular shape or ejector pumps and flow makers where the tanks are in carousel shape. Very minimum air is also fed into the equalization to provide some oxygen to the bacteria and avoid foul smell.

After this process, the water is neutralized in a separate tank with sulphuric acid or soda depending on the level of pH.

AERATION

It is the “heart“ of the plant.

The Aeration Tank is where all transforming phenomena of pollution contained in the wastewater takes place, thanks to bacteria and microorganisms. Bacteria, in the course of their life, grow and multiply themselves. This is possible through two processes: the energetic and the synthesis.

Depending on the size of the tank to be constructed we design both rectangular shape and carousel shape tanks.

It is in the process that the COD, BOD, TSS, surfactants are reduced.

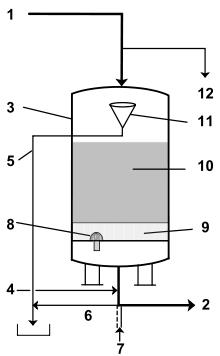

DIFFUSERS / OXYGEN SUPPLY

Fine bubble diffusers are installed in the bottom of the tank. The quantity of air supplied is automatically controlled by a dissolved oxygen-meter, which is positioned inside the aeration tank. It drives the blowers permitting to furnish the exact quantity of oxygen required by adjusting the airflow of blowers.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.