INDO EUROPA TRADING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to INDO EUROPA TRADING COMPANY

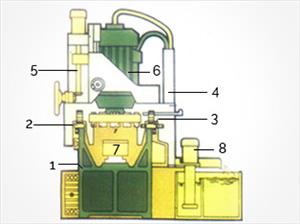

Hot Foil Stamping Machines

Hot foil stamping machines has an exclusive touch to brighten attractive and decorative features on Packs, Boxes, cartons, labels, greetings and wedding cards and other printing items.

These hot foil stamping machinery is especially useful for manufacturers of cosmetics and liquor boxes.

[Hot Foil Stamping Machine]

SALIENT FEATURES

Hot foil stamping machines has three foil stamping units

Three different strokes can be adjusted for printing three different blocks of different length.

Arrangement of one foil jumping is there.

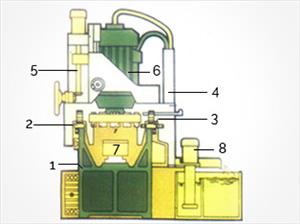

Carton Punching Machine

The Die Cutting Machines. A heavyweight in every right, this hand fed marvel is designed for die cutting, creasing, embossing and half-cutting a variety of materials. Highly standardized and ergonomically manufactured, it can deliver clean jobs on paper, cardboard, corrugated board, leather, plastic and PVC materials. The platen is of high tensile cast iron which can take varied levels of pressure without any strain or defamation. The main driving shaft is equipped with two sets of double helical self lubricated imported polyamide pinions maintained in an all bath. The automatic die cutting machine or platen die cutting machine is also filled with two pairs of protected reduction gears.

These automatic platen die cutting machine are built to lost with superior quality paint and powder coated fittings coupled with silent trouble free operation, making the Die Cutting Machine the most reliable, simple to use and maintenance free machine today.

Control Box

Operation and control oriented, the main electric panel is made up of internationally standardised components of well known brand leaders, enabling precise operation & control.

Salient Features

[Carton Punching Machine]

Totally standardized interchangeable parts.

EN-8/9 Alloy steel shafts and ground pins.

Phosphor Bronze bushes.

SKF/NBC bearings.

Siemens/L&T/T.C. components on control panel.

Checknuts lock system on main flywheel.

Two eccentric impression adjustment bushes.

Uniform platen pressure.

Robust, good looking, silent and efficient.

Standard Accessories

Single 'Dwell' facility.

Wrap around safety device.

Automatic sheet counter.

Two normal chassis.

One standard make-ready plate.

Automatic centralized lubrication system.

Service tools.

accessories on request

Imported make-ready plate.

Steel chassis with adjustable frame bars.

Variable speed control.

Adjustable guide system.

Trip-bar.

Side arm guard.

Fly wheel and drive belt full guard.

VARIABLE IMPRESSION PRESSURE

The presence of two eccentric bushes with visible calibration makes it simple and easy to make quick, minute adjustments to impression pressure. Being independent for each, perfect platen pressure can be achieved by a combination of setting as desired.

ADJUSTABLE ELECTROMAGNETIC CLUTCH & BRAKE SYSTEM

Fine tuned and adjustable at the micron level, the clutch and brake are in perfect electromagnetic synchronization, thus ensuring no overlap between the driving and braking mechanism. This saves considerable energy loss and the conspicuous obsence of all in the system eliminates risk of all reaching the friction surfaces.

U. V. Coating And Curing Machines

UV / IR / HOTAIR COATING MACHINES

UV coating machine is engineered to give uninterrupted Service.

UV curing machine is engineered for low energy consumption.

Engineered for safe operation.

With Combination drying option UV Curing / IR Drying / Hotair.

To be linked to coating equipments like varnish coating, roller coating, offset, screen prints, etc. for high performance coating and curing applications.

For a variety of Substracts & applications.

Full print finishing equipment for duplex board, Varnish- Aquous Varnish, sprit based Varnish and Solvent based Coating.

UV Coating & Curing equipments for paper & boards.

Engineered for operators and machine safety uninterrupted service, low energy consumption and minimum set up / make / changer time.

Adjustable coating weight and coating speed.

Standard sizes are 24' - 30' and 40' width.

UV Curing attachment for offset printing machine is also available

Used Automatic Paper Cutting Machine

We deal in USED Paper cutting machine of different brands such as POLAR, PERFECTA, WOHLENBERG, ITOH, SCHNEIDER, YOSHINO, F.L, HAROLD all machine are Imported in INDIA From Europe, USA, Canada, japan this machine are fully checked and cleaned and can be tested at our warehouse, The machine are available in different size all 76, 78, 90, 92, 115, 132, 137 we also deal in 3 knife trimmer machine used for BOOK production please contact us for your requirement of USED PAPER CUTTING Machine.

Paper Cutting Knives

Guillotine Knives

Heavy duty operation

Combined iron and steel material

High speed steel inlaid material

Super grained TCT inlaid material

Unmatched sharpness and fine finish

High wear resistance

Suitable for all types of paper, cardboard & foils

[Paper Cutting Knives]

Trimmer Knives

Three material grade

1: 5 : 10 advantage

Most sizes available exstock for perfecta, polar, kolbus, wohlenberg and other popular machines

Ideal to reduce drag, draw and dust in your paper trimming

Superior metal fusion and joining technique

Optimally heat treated and precision ground

Uniform cutting edge

Trouble free operation.

Knife Sharpening Machines

Machines Constructions

Machine Bed

Guideways

Machine Table

Grinding Motors

Down-Feed for Grinding Tool

Grinding Motors

Grinding Head Segmental or Cup wheel

Cooling Systen

Electrical Unit

Machine Bed

Welded, modular construction principle. Smooth inner area for good cooling water drainage and easy cleaning.

Guideways

Hardened and ground steel bands for main and side guides, easily exchangeable.

Machine Table (Clamping Type)

Cast Iron table with 'T' slots & Clamps.

Cast iron swiveling table for bevel grinding in one setting up operation, swivelling 360, multiple bearing points with large diameter journals for maximum rigidity Additional clamping sides with 'T' slots & clamps.

Mechanically Table locking, by hand.

Grinding Head Carriage

Heavy casting mounting on four reels with eight New-Departure dust proof ball bearings which act as rollers. Four reels guide the carriage in the carriage ways of the bed. The sliding base, mounted on the top of the carriage, is adjustable to feed the griding segmental or cup-wheel to the knife. The motor base can be swivelled 10 to 25 degrees, so that the knife can be ground either straight or concave as paper knives require only 5 degrees swivel of motor base.

Down-Feed for Grinding Tool

Multiple spindle system for play and weight equalisation. Automatic Down-Feed also available (Optional).

Grinding Motors

SIEMENS or NGEF Brand.

Grinding Head

Cylindrical type bonded to flange for light grinders, segmental heads for heavy grinding machines.

For quick re-setting or changing of the segments, an easily accessible changing station is situated at the rear of the machine.

To ensure vibration – free running, all grinding wheel flanges and segmental heads are fitted with adjustable balancing weights. For obtaining maximum segment use, patented segment savers can be used.

Cooling System

Water tank attached with the machine. Cooling fluid application by the electro-coolant pump.

Electrical Unit

All electrical controls are housed in the master panel board.

Maxi Cutting Sticks

Maxi Cutting Sticks is for Paper Cutters And Trimmers

Imported cutting sticks for POLAR and PERFECTA machines. Maxi Cutting Sticks is also available for indian machines.

Manufactured for use on all paper cutters and 3 knife trimmers Range

All machine types, up to the very latest models and includes all paper cutters and 3 knife trimmers worldwide.

Come in range of materials

Compatibility of material to knife

Expectation of longevity

Environmental issues and recycling

Produced from 100% prime material

Manufactured to extremely high tolerances in a modern factory

Produced in a range of materials

uPVC (Red) - Standard Knife - Cutters & Trimmers

HDPE (White) - All Knife qualities except TCT - Cutters only

PP (Grey) - All knife inc TCT - Cutters & Trimmers

PA (Nylon) (White) - HSS & TCT - HSS/TCT Trimmers

Used Offset Printing Machines

Welcome To Indo Europa - providing the complete solution to your reconditioned printing equipment or new printing machinery requirements since 1926.

From quality approved reconditioned printing machinery and refurbishing services to the very latest models on the market, we are a powerful force, designed to meet the needs of the modern business world.

Komori, Heidelberg, Mitsubishi, Man Roland - The worlds leading manufacturers- and just a few of the prestigious names you can expect to find here at Indo Europa along with dependable technical expertise formed from over 100 years industry experience. However elusive the printing machine you are interested in, thanks to our extensive database, we will be able to source it.

Our stock list shows actual presses - none are invented in order to draw customer interest. We only show equipment we own, have committed to purchase.

If you are looking for a reliable and experienced used printing equipment supplier offering unbeatable prices and excellent service both now and in the future.

Thread Book Sewing Machines

IndoEuropa is one of the leading Manufacturers engaged in developing and producting Book Binding Machineries such as Thread Book Sewing Machine, thus serving the Printing and Book Binding Industry for nearly seven decades.

IndoEuropa has adopted latest technology in its quest to achieve perfection, speed, quality and consistency. The company has installed a record number of machines through the length and breadth of the country.

Production Speed

The construction and working of the machine permit maximum speed of 70 sections per minute. However, the actual output depends upon size of section, type of paper, kind of fold and the skill of the operator.

Optional

Cutter for Automatic Cutting of Books.

For stitching Books of Size 18" x14" or 24"x14" separate attachment can be provided.

Our commitment towards continuous product development may result in changes in the above specifications without notice.

Paper Cutting Sticks

Description / Specification of Paper Cutting Sticks

We are involved in offering a wide range of Paper Cutting Sticks to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Paper Cutting Sticks. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.