HYDROFLEX PIPE P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HYDROFLEX PIPE P LTD.

Stainless Steel Hose

Description / Specification of Stainless Steel Hose

We are involved in offering a wide range of Stainless Steel Hose to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Stainless Steel Hose. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Braid

When pressure is applied, unbraided hose tends to elongate axially; to restrain this, an external layer of SS wire braid is provided. The braid also makes the assembly pressure compatible.

Sometimes two or even three layers of braiding are provided for high pressure applications. The braiding is highly flexible and follows the movement of the hose. The braid is normally manufactured in SS 304 wire. However SS 316 and 321 braids can also be manufactured. We also supply wire braid in different configurations as per customer specifications.

Advantages Of Flexible Metal Hose

High physical strength combined with light weight.

Suitable for wide temperature range (-200° C to + 550°C)

Good corrosion resistance. Resistance to fire, moisture, abrasion and penetration.

Absorbs vibration and noise from pumps, compressors, engines etc.

Compensates for intermittent or constant movement.

Compensates for thermal expansion of contraction of piping.

Corrects problems of misalignment.

A flexible and quick alternative for rigid piping in difficult locations.

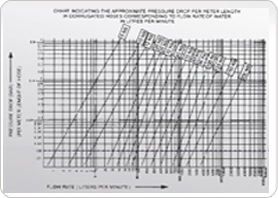

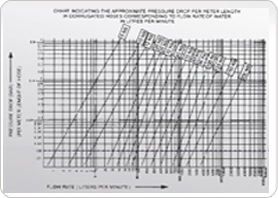

Pressure Loss

The pressure loss in corrugated hoses is 100% higher than in new welded steel pipes, because the bore of acorrugated hoses is not smooth. This means that in the case of corrugated hoses an increase in diameter of 15% is required to reduce the pressure loss to the value of the pressure loss in steel pipes..

Assemblies And Welding

HYDROFLEX PIPE PVT. LTD. hose assemblies are engineered to perfection in flexibility, strength and reliability. We can provide a corrugated stainless steel hose assembly that meet your most demanding technical specification. We can supply the hose complete with any all types of end connections in various types of materials. The end connection are TIG welded to hose. HOSE ASSEMBLIES CAN BE SUPPLIED UNDER ANY THIRD PARTY INSPECTION.

Welding procedures and welders are qualified as per (ASME section-IX) by Moody International & as per ISO 15609 - 1 : 2004 by DNV..

Testing And Certification

All unbraided hoses are subjected to leak detection test using compressed air.

All assemblies are checked for dimensional accuracy and pressure tested.

Test certificates for pressure tests carried out will be provided.

Test stipulated by BS 6501, Part-1:2004/ISO 10380:2012 are conduced periodically.

Raw material test certificates showing the physical and chemical properties will be furnished on request.

Radiography, DP. test, will be carried out against specific customer requirements.

The products can be supplied under any third party inspection.

We can supply the hose assembly with "CE" marking as per PED 97/23/EC against customers requirements.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.