HILDA AUTOMATION

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HILDA AUTOMATION

Automatic Single Side Labeling Machine

Max Label Web Width used is 125mm / 210mm / 260mm.

Label length will be 10-200mm

Label Reel Core Diameter will be 75mm or 38mm

Label material used Most types currently available

Machine Linear speed is 4-35m/min

Weight (approx) 150Kg

PLC Control Siemens S7

Integrated modem Siemens (optional)

Label gap sensor Optical / microswitch

Product sensor Clear object diffuse sensor

Compressed Air 60-80psi (if overprinter fitted)

Electrical Supply 1Ph 230V 50-60Hz

Electrical Consumption 1.5kW

Automatic Mini Wraparound Labeling Machine

Max Label Web Width 125mm / 210mm / 260mm

Label length 10-200mm

Label Reel Core Diameter 75mm or 38mm

Label material Most types currently available

Machine Conveyor 90w 50rpm variable speed

Conveyor length 1.5m / 2m

Conveyor width 3 1/4" 4 1/2" 6" Delrin slat chain / stainless steel

Linear speed 4-30 metres /min

Overal dimensions (LxWxH) 1500mm x 955mm x 1000mm

Working height 900mm +/-50mm

Weight (approx) 150Kg

PLC Control Siemens S7

Integrated modem Siemens (optional)

Label gap sensor Optical / microswitch

Product sensor Clear object diffuse sensor

Compressed Air 60-80psi (if overprinter fitted)

Electrical Supply 1Ph 230V 50-60Hz

Electrical Consumption 2.0kW

Automatic Front And Back Labeling Machine.

Max Label Web Width 125mm / 210mm / 260mm

Label length 10-200mm

Label Reel Core Diameter 75mm or 38mm

Label material Most types currently available

Conveyor Length 2.0m / 3.0m (or to suit application)

Conveyor Width 3 1/4" 4 1/2" 6" Delrin slat chain / stainless steel

Linear speed 4-35m/min

Overal dimensions (LxWxH) 2000 x 800 x 1300

Weight (approx) 200Kg

PLC Control Siemens S7

Integrated modem Siemens (optional)

Label gap sensor Optical / microswitch

Product sensor Clear object diffuse sensor

Touchscreen TFT 4" 640x480 resolution

Compressed Air 60-80psi (if overprinter fitted)

Electrical Supply 1Ph 230V 50-60Hz

Electrical Consumption 2.0kW

Automatic Linear Head Cup Rinsing Filling And Sealing Machine

Fully automatic linear operation for 100ml - 300ml ready made cups.

Maximum production speed of 74-80 cups/min.

Machine fully in S.S - 304 and product contact parts in S.S - 316.

Machine can be custom designed for Folio / Film as per requirement.

UV sterilization done on the empty cups before filling.

Provided with PLC control.

Belt type conveyor for automatic unloading.

Automatic Bottle Rinsing Filling And Capping Machine

Fully automatic Monoblock operation for 200ml - 2000ml bottles.

Can run PET bottles with air conveyor and Glass bottles with in-feed slat conveyor.

Maximum production speed 30/60/90/120/150 bottles/min.

Machine fully in S.S - 304 and all product contact parts in S.S - 316 quality.

Machine can be made for hot fill products or cold fill carbonated drinks.

UV sterilization for caps before capping operation.

Fitted with PLC control.

Elevator / Vibrator for automatic applying of caps.

Optional: Batch coder, Shrink tunnel

Automatic Bop.P. (Hot Melt) Labeling Machine

Labeling Machine 45046.jpg)

Fully automatic linear operation for 200ml - 2000ml bottles.(with certain change of parts).

Maximum production speed of 60 / 90 / 120 / 200 bottles/min.

Machine is built fully in Stainless Steel.

Height adjustments to suit various bottle sizes.

Imported gluing unit sprays minimal quantity of hot melt adhesive (very minimal wastage).

No cleaning of the nozzle or glue unit, before production (less maintenance & saves time).

Minimal change-over time, to shift from one size to an another size of the bottle.

Fitted with PLC control.

Cup Filling Sealing And Cutting Machine For Jelly

Fully automatic linear operation for 10ml - 50ml ready made cups.

Can fill Jam/Jelly/ Sauce/ Ketchup/ Chocolate sauce/ viscous products etc.

Maximum production speed of 200 - 400 cups/min.

Machine fully in S.S - 304 and every product contact part in S.S - 316 quality.

Machine can be tailor-made for Foil or Film as per requirement.

Volumetric multi-head fillers for filling.

Pick and place system for pre-cut AI. foil is also made.

Suitable for a variety of containers : Round, Square, Hexagon, etc.

Standard or custom designed and with higher speeds are also available.

Camfield mechanism for accurate indexing.

Fitted with PLC control.

Proper drain tray for effective removal of water.

Effective CIP system for cleaning of machine.

Automatic filling machines.

Biscuit And Cream Filling Sealing And Cutting Machine

Description / Specification of Biscuit And Cream Filling Sealing And Cutting Machine

We are involved in offering a wide range of Biscuit And Cream Filling Sealing And Cutting Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Biscuit And Cream Filling Sealing And Cutting Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

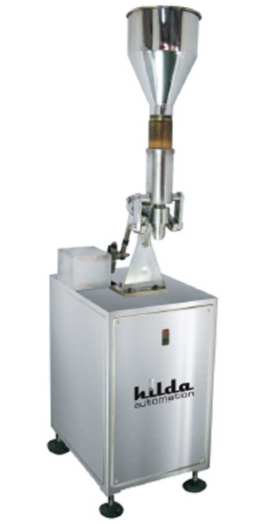

Filling Machine With Hopper Piston System

Fully automatic Rotary Indexing operation.

Suitable for viscous products.

Maximum production speed of 60 - 70 bottles/min.

Machine fully in S.S - 304 and product contact parts in S.S - 316 quality.

Filling system based on Volumetric syringe 3/2 way rotary valve.

Options available : 2,4,6 and 8 head.

Mechanically operated with drip-less filling.

Standard or custom-designed machine with higher speeds are also available.

Crown Capping Machine

Fully automatic operation.

Machine structure in Stainless Steel.

Rotary Indexing type mechanism.

Can be made for production speed upto 36 caps/min with single head.

Vibrator with chute for automatic loading of cap.

Option available : Single head or multi head.

Standard or custom designed machine with higher speed are also available.

High Speed Screw Capping Machine

- Fully automatic operation.

- Stainless Steel machine structure.

- Belt type capping mechanism.

- Can be made for production speed upto 60-90 caps/min.

- Elevator with chute for automatic loading of caps.

- Standard or custom designed machine with higher speed are also available.

Screw Capping Machine

Fully automatic operation.

Stainless Steel machine structure.

Rotary Indexing type mechanism.

Can be made for production speed upto 36 caps/min.

Vibrator with chute for automatic loading of crown caps.

Option available single head or multi head.

Standard or custom designed machine with higher speed are also available.

Container Sealing And Cutting Machine

Fully automatic Rotary Indexing operation.

Machine structure will be of M.S. powder coated.

For guaranteed sealing in laminated films.

Sleek and compact design.

Can be made to produce speed upto 100 containers/min.

Sealing media required - printed/plain laminated film in roll form.

With in-feed and out-feed belt conveyor.

Separate electrical panel to control individual film in roll form.

Separate electrical panel to control individual temperature setting.

VFD used to increase or decrease the speed of the conveyor.

Choice of standard or custom designed machine with higher speed are also available.

Semi Automatic Sealing Machine

Semi-Automatic operation. (Manual loading and unloading)

Table top model.

Sleek and compact design.

Sealing media requirement - printed/plain laminated film in roll form.

Specially designed for least production industry.

Single container sealing at a time.

Can seal round, oval, square, rectangular Plastic containers.

Machine built fully in Stainless Steel.

Speed solely depends upon the operator.

Shrink Sleeve Applicator With Tunnel

Description / Specification of Shrink Sleeve Applicator With Tunnel

We are involved in offering a wide range of Shrink Sleeve Applicator With Tunnel to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Shrink Sleeve Applicator With Tunnel. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Automatic Neck Sleeve Applicator (Tamper Evident Seal)

45058.jpg)

Fully automatic operation Fitted with digital PLC control.

No bottle - No sleeve feature (eliminates wastage).

Rotary cutting system.

Can handle round glass/plastic bottles.

Speed of 40 bottles to 300 bottles/min depending on the cut length of the sleeve.

Servo motors for more accuracy.

Height adjustments to suit various bottle sizes.

Eye mark sensor for accuratecutting in printed sleeves.

Can easily be synchronized with a tunnel.

Sleeve Cutting Machine

Fully automatic operation.

Machine structure will be of M.S. powder coated.

Servo motors for more accuracy.

Fitted with digital PLC control.

Eye mark sensor for accurate cutting in printed sleeves.

Cut length : 20 to 310 mm.

Perforation : Horizontal / Vertical perforation.

Purpose : To cut the film in specified length from the roll form.

Speed : 350 - 400 cuts/min. at 50 mm. length.

Standard or custom designed with higher speeds are also available.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Labeling Machine 45046.jpg)