GUJRAT POLYPET

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to GUJRAT POLYPET

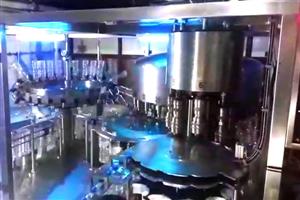

Automatic Rinsing Filling And Capping Machine

This filling line includes combination of mechanical & pneumatic operation, with mechanical intermittent rotation for rinse, fill & cap. The production capacity of this line reaches 1680 bottles/hour at 1000 ml.

Features:

• Compact in size, Rotary design

• Most parts are made of Stainless Steel

• Multistation with Time pressure filling

• NO bottle NO rinse/NO bottle NO fill system provided

• Compact electrical panel with Infeed Air Conveyor and Outfeed Slat belt Conveyor

• Easy and quick change over system provided for different volume filling

Main Technical Specifications:

• Production Capacity : 1680 bottles/hour (at 1000 ml)

• Washing Head : 2

• Filling Station : 3

• Capping Station : 1

• Filling Accuracy : ± 2 %

• Compressed Air : 3 - 4 cfm at 6 kg/cm3

• Power Consumption : 3.5 hp

• Gross Weight (kg) : 1500

• Dimensions (LxWxH) (mm) : 1300 x 1500 x 2400

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.