FOWLER WESTRUP (INDIA) P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FOWLER WESTRUP (INDIA) P.LTD.

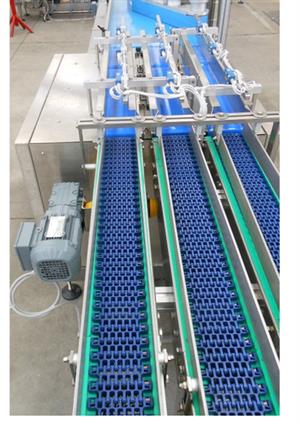

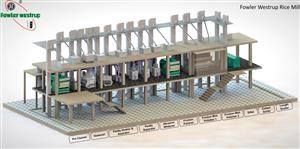

Rice Milling

Rice Milling machinery is playing an important role in harnessing the huge Agricultural potential of India. Fowler Westrup which has pioneered world class cleaners at an affordable rate to the Indian Agricultural Processing industry has again brought in a world class product to change the Rice Milling scenario in the country.Effective milling of Rice depends on skilled miller, good Paddy and good machines.Fowler Westrup in collaboration with the Japanese leaders M/s. Yamamoto Co.Ltd is bringing revolutionary product which will give the best yield with the lowest power consumption, thus contributing to the increase in margin for the miller. When the miller is squeezed between the higher input cost and the lower realization for the output rice, every percentage improvement in efficiency will go a long way to make their profit grow.

Following are some of the models which are readily available :

- Destoner - CSP 502

- Paddy Husker - YSA 100

- Paddy Separator - SE 500

- Abrasive Whitener - XPA 25

- Abrasive Whitener - GPA 50

- Friction polisher - XPF 50 and XPF 50 D

- Grading Sifter - SF 301

Other models can be offered on request and after technical discussions.

Opto Electronic Color Sorter

The AUTO SORT sorter is an intelligent precise rice sorter which uses a robust 2048 pixel high speed line scan CCD camera combined with image processor, fully trainable to suit needs through a refined color training process for flawless elimination of unwanted material.

Applications:

Rice: Raw, Steamed and Parboiled

Grains: Paddy, Maize, Wheat

Seeds: Sesame Seeds, Poppy Seeds, Sunflower Seeds, Pumpkin Seeds, Watermelon Seeds, Mustard Seeds, Tamarind Seeds

Pulses: Black gram, Bengal gram, Moth Bean, Pigeon Pea (Toor Dal), Fried Gram, Black Beans, Green Peace, Sorghum

Spices: Pepper, Cardamom, Dehydrated Garlic, Cumin Seeds, Coriander

Dry fruits: Broken / Whole cashew nuts

Others: Millet, Salt, Tea, Coffee, Rice Flakes (Poha)

Features :

- Very High resolution inspection (from 0.3mm onwards)

- Long lasting and low power consuming LED lights

- Snapshot processors for high precision sorting.

- Fit & Forget operation

- Precise rejection through high speed serviceable ejectors

- Easy setup through interactive touchscreen

- Best rejected ratio

- Simultaneous removal of chalky rice without reduction in throughput.

- 24x7 support

- Excellent service network across India.

Electronic Rice Sorter

The AUTO SORT sorter is an intelligent precise rice sorter which uses a robust 2048 pixel high speed line scan CCD camera combined with image processor, fully trainable to suit needs through a refined color training process for flawless elimination of unwanted material.

The product is loaded through the top in feed hoppers and then passes through vibrators which send an even stream of the product down the plain chutes monitored by cameras which send data in real time to the processor which compares the product with the colour trained template and rejects the unwanted material by blowing them away through pneumatically controlled ejectors nozzles to reject bin and the accepted material passed on to the accept bin. The second set of grooved chutes does a second run of the reject and reclaims and remaining good material. The accept and reject are the best in the industry.

- Very High resolution inspection (from 0.3mm onwards)

- Long lasting and low power consuming LED lights

- Snapshot processors for high precision sorting.

- Fit & Forget operation

- Precise rejection through high speed serviceable ejectors

- Easy setup through interactive touchscreen

- Best rejected ratio

- Simultaneous removal of chalky rice without reduction in throughput.

- 24x7 support

- Excellent service network across India

Opto Electronic Color Sorter Dal Sorting

Benifits :

Purity of product is the most sought after value in business. Purity of product commands its premium price. Customer loyalty is guaranteed if purity of product is assured . The Autosort MCR of Fowler Westrup with its winning features and highly customizable user friendly interface and robust hardware ensures that you always can keep up the promise of purity thereby assuring you of a guaranteed market and good profits . With the industry’s best accept and reject rates and chalky grain removal without reduction in throughput any competitor is left far behind and a new better standard of quality has been set . Automatic features reduce dependency on operator and ensure a truly fit and forget self learning and maintaining system .

Features :

- Very High resolution inspection (from 0.3mm onwards)

- Long lasting and low power consuming LED lights

- Snapshot processors for high precision sorting.

- Fit & Forget operation

- Precise rejection through high speed serviceable ejectors

- Easy setup through interactive touchscreen

- Best rejected ratio

- Simultaneous removal of chalky rice without reduction in throughput.

- 24x7 support

- Excellent service network across India

Sooji Sorter

The AUTOSORT MC Range uses a rapid sequence of different coloured lights to obtain ‘more than colour information’ from the product. Often, even very similar colours can be differentiated. The infra-red capability improves detection of foreign bodies. The camera information is processed by an ultra-fast digital signal processor, and commands are sent to one or more ejectors to remove the unwanted item efficiently.

The MC-A is specifically configured for efficient sorting of difficult to handle, lightweight products such as green herbs or flakes. After being spread on a vibratory feeder, the product accelerates down a chute and is inspected by the 2048 pixel line-scan camera. Defects and contaminants are removed by short puffs of air from ejectors built into the feed system. The unique shape of the chute and configuration of ejectors ensure very high efficiency of defect removal and low wastage of good product.

Application:

Dehydrated Herbs, Chives, Coarse Powders, Semolina (Sooji)

Potato Flakes, Dry & Frozen Foods, Breakfast Cereals, Soya Granules, Chilli Flakes,

Dehydrated Onions, Psyllium Husk, Sugar & Other Light Weight Products

Benefits :

Natural materials contain impurities and less-than-perfect product. By removing discolouration and contamination, the quality and value of the finished product is increased, or lower grade raw material can be used. The customer will be rewarded with consistent quality product. Also food safety is enhanced by ensuring that foreign bodies and contamination are removed before it reaches the consumer. Added value all round.

Features :

- Optical lighting in four bands from visible to infra red

- Rapid LED lighting

- Inspection in 2, 3 or 4 specific parts of the spectrum

- High resolution cameras from 0.3 mm

- Flexibility – Optional mono-chromatic Fluorescent lighting to suit product

- 2 sizes: 672mm, 1344mm

- Compact Footprint

- Independent vibrator

- Food grade Stainless Steel construction

- 64 or 128 fast ejectors. Can be configured to 128 or 256 ejectors for precise ejection

- Minimum good product removal

- Easy setup with large touch screen

- Facility to store and recall several programme modes for multiple products

- Auto-calibration and self cleaning

- Remote maintenance through modem connection

Oil Filtration And Regeneration System

Benefits

The importance of good quality power makes it very important that all the equipments give their best performance. Transformers being a key equipment, it becomes imperative to maintain optimal insulation properties of the transformer oils by rigid control over moisture, dissolved gases and particulate contamination. Failing in this results in considerable decrease in its BREAK DOWN VOLTAGE, INSULATION RESISTANCE, and increase in DIELECRIC LOSS FACTOR, leading to breakdowns of transformers. Conditioning saves the cost of using new oil frequently and also increases the life of the transformer. Even commercial new oil is seldom sufficiently pure for direct use in high voltage equipment, being subject to contamination in transport containers and liable to absorb unacceptable contaminants and moisture.

Filtration Eliminates

- Solid impurities

- Dissolved water

- Dissolved gases

Engineered to meet your needs

Fowler Westrup (India) Private Limited takes pride in its ability to provide equipment specifically designed to meet customer requirements and specifications at reasonable cost.

Customer Service

- INSTALLATION

- COMMISSIONING

- COMPLETE TURNKEY APPLICATIONS

- SPARE PARTS

- SERVICE AND MAINTENANCE SCHEMES

- TECHNICAL SUPPORT NETWORK

Drum Pre Cleaner

The Fowler Westrup Drum Pre-Cleaner is simple drum type rotating machine used for primary course cleaning at intake section of processing plant or silos in order to relieve the following machines & material handling equipment. The drum pre-cleaner separates coarse impurities such as paper, wood pieces, leaves, cobs, stones and long sticks etc.

Applications

Salient Features

- Steel construction

- Enclosed housing with inspection cover as well as assembly or servicing cover

- Variable drum perfections based on customer requirements

- Guide spiral inside the drum to convey the material to the outlet end

- Scraper cleaning

- Spout dust aspiration

- Equipped with inlet spout and inlet channel

Brushing Machine

Fowler Westrup Brushing/polishing machine can be used as the first step in the fine cleaning process of flower, vegetable and grass seeds. Machine is suitable to remove hairs, ears and wings from seeds, threshing seeds out of pods or flowers, splitting twin seeds, polish seed etc.

Applications

Seed Industry: Flower seeds, Vegetable seeds, Grains, Grass seeds, Spices & more..

Edible oil industry: Removing cake from the shell of seeds..

Research institutes: Treating small lot of expensive seeds..

Advantages

- Gentle processing

- High capacity

- Outstanding removal of skins

- Compact design

- trouble free cleaning

- Cost effective

Special Features

- Variable speed drive

- Beaters (instead of brushes)

- Outstanding removal of skins

- End outlet with aspiration, built on fan, and cyclone.

Laboratory Machine Gravity Separator

We offer a high quality range of Laboratory Machine. here we offer LA-K Laboratory Machine Gravity Separator. The LA-K Laboratory Machine Gravity Separator for laboratory use is designed for batch and continuous flow separation of small volumes of seed or gaind, which have already been separated with regard to width, length and thickness.

The gravity separator exploits the smallest differences in the specific weight of the product and it is therefore possible to separate heavy kernels with high germination ability from light and less valuable kernels. The Gravity separator can also be used in laboratories for recycling on in chemical factories.

Continuous separation capacity is up to 100 kg per hour on wheat basis.

Spiral Separator

The Fowler Westrup spiral separator is ideal for spreading round seeds from split, flat or oblong seeds or weed seeds by means of gravity. High recovery rate can be achieved with its gentle handling and compact design.

Applications

Seeds: Paddy, Wheat, Corn, Oil seeds, Vegetable seeds & more..

Spices: Pepper, Coriander seeds & more..

Fruits & Vegetables: Soya bean, Rapeseeds, Mustard, Green peas, Blackcurrant & more..

Food Industry: Chocolates, Candies & more..

Salient Features:

- Adjustable deflectors/Fingers to ensure optimum performance by reducing grain speed

- Adjustable slide gate at the bottom to recover near flat grains

- Cabinet with different number of spirals, each with 8” flights; with different helix angles.

- Feed hopper and one inlet for each spiral

- Two outlets – one for prime product and one for waste

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.