FORTUNE PHARMA TECHNOLOGIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FORTUNE PHARMA TECHNOLOGIES

Zero Hold Up Filter Press

Zero hold up filter presses cartridge assembly consists of plates, perforated screens, spacers and filters media the liquid spreads out equally on each plate fitted with filter media filtrate flows through precisely made on sides of plates and collects in the shell, which then comes out through the outlet in the process solids are evenly distributed on each plate. The cake is then cleaned from the filter material and used again for viscosity of the oil & liquid & with the amount of sediment contained therein. There are various combinations available in size & number of plate to give different filtration area & cake holding capacities to meet your process requirement. The work man ship finish & make of components ensure best quality to meet the fortune Pharma Technologies Requirements.

Salient Features.

- Single pass filtration with no solid by pass

- No scavenger arrangement required

- The top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake.

- Available with centrifugal/ gear/ lobe pump

- Fitted with pressure gauge, safety valve, air vent , sampling port

- High flow rates

- Low pressure drop

- Positive sealing arrangement to avoid by passing

- Easy to operate & low maintenance

- Cove are “O” Ring sealed

- High temperature & high pressure design are available

- Housing are permanently piped

- Large-area heavy-duty baskets

- The filtration area and cake holding capacity can increased or decreased according to requirement

- Filter press is available in two size. Deep plate for large percentage of cake holding and shallow plate for small percentage of cake holding capacity

- SS pump mounted on SS trolley with heavy duty trust ball bearing caster wheels for easy movement

- Provide with by pass system and sample collecting device

- SS jacket can be provide for hot filtration (optional)

- Components are argon are welded & polished to mirror finish

- Push button station will be provided with machine also

- Recirculation line be provided as per client requirement.

- All housings made from ss316/ss316L & ss304 are mirror polished

- Size available models 8”14”18”24 & 33” Diameter

- Available models 8”14”18”24 & 33” plate Diameter

Application:

- Sugar syrup based liquid oral for pharmaceutical

- Sugar syrup for soft drink industries

- Pre coat filter for breweries.

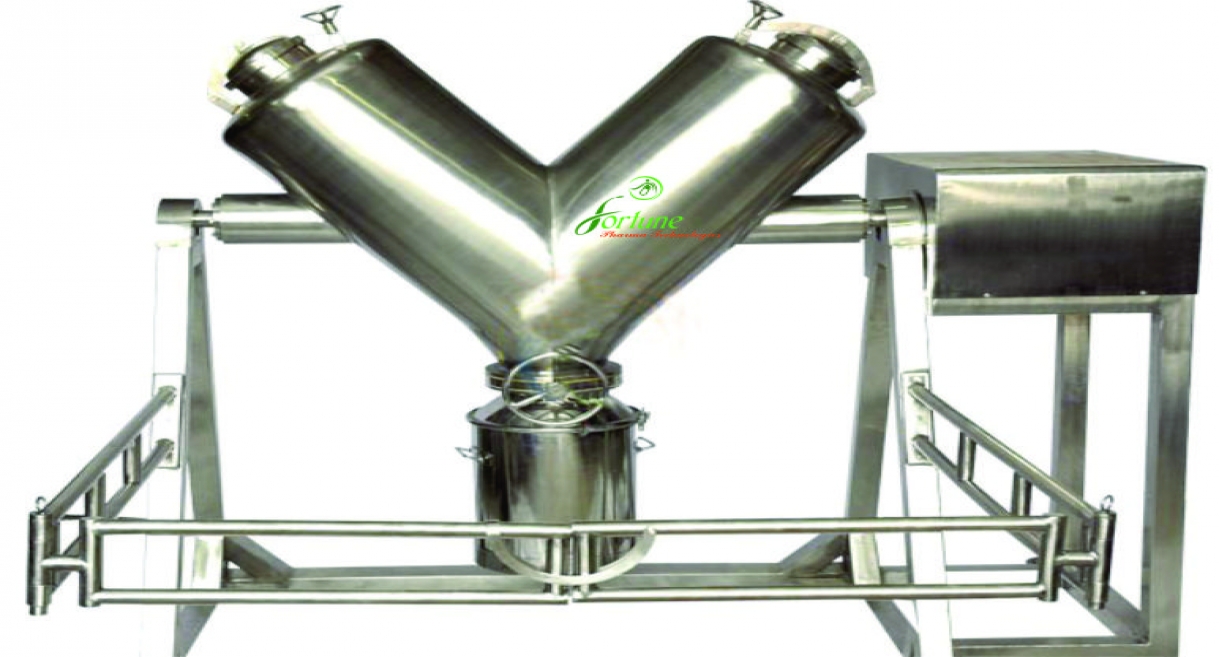

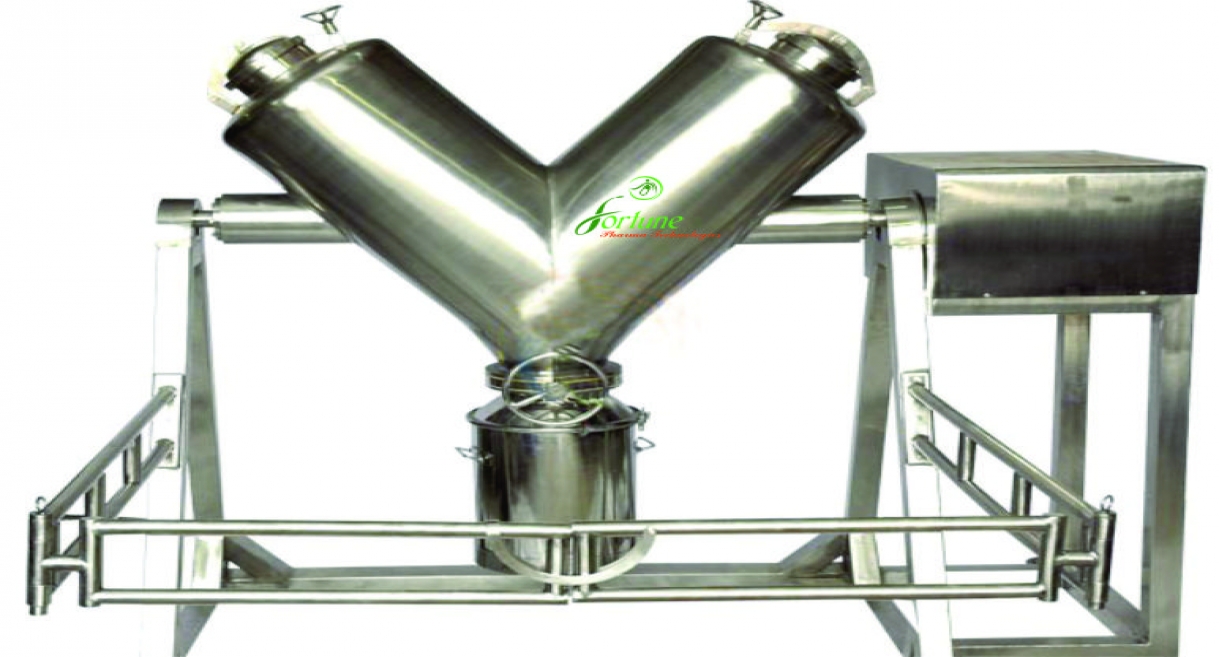

V Blender

The ‘V’ Blender Pharmaceutical Gives Best Result For Granules For Granules It Can Use For Pharmaceutical Food, Chemical And Cosmetic Products Etc. The Type Of Material Gets Sufficient Continuous Movement Due To Their “V’ Shape Body. . We Are A Prime ‘V’ Blender Manufacture And Supplier From Thane Maharashtra. We Make ‘V’ Blender According To The Client’s Specification As Needed. Our Granules ‘V’ Blender Needs Low Maintenance And Has Low Power Consumption. Two Third Of The Volume Of The ‘V’ Blender Is Filed To Ensure Proper Mixing Products. Offered ‘V’ Blender Machine Can Be Availed At Affordable Price All Contact Part Made Of Ss316 Or Ss316L Quality Material Non-Contact Part Made Of Ss304 Or Cladded.

Features.

- Discharge output via. Butter fly value. (Pneumatic discharge can be provided as per client requirement)

- Safety Guard provided with limit switch (to avoid accident )

- To in chance the mixing finger type baffle are provided centre of main body

- Internal finish 220 grits to 320 grits and outside matt finish 180 grits

- Rotation specially designed high efficiency duplex chain drive/ Direct Drive by Coupling.

- ‘V’ shape & slow speed of rotating gives continuous movement to the granules, result in good quality

- Easy for cleaning

- Simple design and minimum maintenance

- Capacity available in 10 to 3000 ltrs & 2 to 10ltrs for R & D models

- Manual rotating facility with hand wheel for inching

Other Options Available

- Flame proof construction drive motor along with flame proof c. panel / starter

- Vacuum loading facility for material charging

- VFD

Octagonal Blender

The Octagonal Blender Pharmaceutical Gives Best Result For Granules For Granules It Can Use For Pharmaceutical Food, Chemical And Cosmetic Products Etc. The Type Of Material Gets Sufficient Continuous Movement Due To Their Polygon Shape Body We Are A Prime Octagonal Blende Manufacture And Supplier From Thane Maharashtra. We Make Octagonal Blender According To The Client’s Specification As Needed. Our Granules Octagonal Blende Needs Low Maintenance And Has Low Power Consumption. Two Third Of The Volume Of The Cone Blender Is Filed To Ensure Proper Mixing Products. Offered Octagonal Blender Machine Can Be Availed At Affordable Price. All Contact Part Made Of Ss316 Or Ss316L Quality Material Non-Contact Part Made Of Ss304 Or Cladded.

Features:.

- Discharge output via. Butter fly value. (Pneumatic discharge can be provided as per client requirement)

- Safety Guard provided with limit switch (to avoid accident )

- To in chance the mixing finger type baffle are provided centre of main body

- Material loading unloading charging drum arrangement provided with mechanical/ hydraulic trolley

- Internal finish 220 grits to 320 grits and outside matt finish 180 grits.

- Rotation specially designed high efficiency duplex chain drive

- Octagonal shape & slow speed of rotating gives continuous movement to the granules, result in good quality

- Easy for cleaning

- Simple design and minimum maintenance

- Capacity available in 10 to 10000 ltrs& 2 to 10ltrs for R & D models.

- Manual rotating facility with hand wheel for inching

Other Options Available

- Flame proof construction drive motor along with flame proof c. panel / starter

- Vacuum loading facility for material charging

- PLC with HMI

- VFD

Tray Dryer

A Tray Dryer Is An Enclosed Insulated Chamber In Which Trays Are Placed On Top Of Each Other In Trolleys. Tray Dryer Are Used Where Heating And Drying Are Essential Parts Of Manufacturing Process In Industries Such As Chemicals, Dye Stuff, Pharmaceutical, Food Products, Colours Etc. We Can Also Supply As Per The Clients' Requirements And Specifications. We Supply Tray Dryer That Is Adequately Designed By Our Designers And Adroit Personnel Who Take Every Care In The Fabrication Of A Durable And Highly Efficient Range Of Machines. Available In Various Models Such As 12 Trays, 24 Trays, 48 Trays, 96trays, These Are High In Performance And Low On Maintenance. The Significant Traits Of Our Exclusive Array Include The Following: Models: 12 Trays, 24 Trays, 48 Trays, And 96 Trays

Construction-

- Robust constructionn

- Built on formed angles of 3mm thick sheet and suitably reinforced with angles and sections

- External walls are manufactured from 1.6mm thick stainless steel sheets of 304 qualities

- The internal of the dryer is built of 1.6 mm thick SS 304 quality sheets insulated with minimum 50 mm thick glass wool insulation and caddied with SS polished sheets

- Fresh air inlet through 20 micron pp cloth filters and a adjustable air outlet flap and a door at the front

- Explosion proof door is locked with the help of spring loaded ball latches with suitable pressure.

- To prevent leakages door lips are having neoprene rubber gasket

Finishing-

- Designed and manufactured as per GMP standard

- Aesthetic look

- Buffed externally to 150 grit matt finish

- Internally buffed to 220 grit mirror finish

Electrical Heating-

- The Air inside the Tray Dryer is heated by "U" tube S.S.304 / Heaters

- The heaters are fitted on the sides of the dryer to facilitate uniform heating.

- Maximum temperature attained inside the dryer is 100' C

- The temperature is indicated and controlled by a Digital Temperature indicator cum controller over full range of heating load

- The total heating load for it will be

- 12 Trays Dryer - 4 KW

- 24 Trays Dryer - 6 KW

- 48 Trays Dryer - 12 KW

- 96 Trays Dryer - 24 KW

- To prevent the heaters from becoming red hot these are inserted inside tubular pipe

- The terminals of the heaters are brought outside the dryer to make it safer for operations for solvent based products

Vibro Sifter

Operation: The Vibro Sifter Offered By Us Is High Class Equipment. Our Vibro Sifter Machines Are Available With A Wide Range Of Possible Screen Size (Mesh) Options For Multiple Desk Separation Is Also Possible. The Precision And Easy Operation S Of Our Product Make The Best High Speed Vibrating. Our Range Finds Huge Uses In Pharmaceutical And Beverage Industries For Separate Solid And Liquid Particles From Composition Our Entire Endeavour Lies In Manufacturing High End Quality Of Vibro Sifter. Our Wntire Product Line Is Manufactured Using Advance Technology. We Are Offering Vibro Sifter To Our Client At Cost Effective Prices

Special Features:

- GMP construction with ss316/ss316L/ss304 contact part.

- Double and triple desk unit with different screen can be provided easy to dismantle for cleaning screen.

- Portable unit with higher output.

- Model available :- 12”, 20”, 30”, 36”, 48”, 60”.

- Machine available with flame proof

- Compact vibratory design for high speed & dust free sieving.

- Easy dismantling and cleaning of contact parts.

- Three phase motor operated

- Specially designed spring.

- Long screen life.

- Modle Output Kg. / Hr. FPT 12 5-50 FPT20 30-175 FPT30 40-300 FPT36 50-450 FPT48 200-750 FPT60 200-1450

Document

Documentation Like DQ, IQ, OQ, Manual and FAT provided with the machine

Double Cone Blender

The Double Cone Blender Pharmaceutical Gives Best Result For Granules It Can Use For Pharmaceutical Food, Chemical And Cosmetic Products Etc. The Type Of Material Gets Sufficient Continuous Movement Due To Their Conical Shape Body. We Are A Prime Double Cone Blender Manufacture And Supplier From Thane Maharashtra.We Make Double Cone Blender According To The Client’s Specification As Needed. Our Granules Double Cone Blender Needs Low Maintenance And Has Low Power Consumption. Two Third Of The Volume Of The Cone Blender Is Filed To Ensure Proper Mixing Products. Offered Double Cone Blender Machine Can Be Availed At Affordable Price. All Contact Part Made Of Ss316 Or Ss316L Quality Material Non-Contact Part Made Of Ss304 Or Cladded.

Features:.

- Discharge output via. Butter fly value. (Pneumatic discharge can be provided as per client requirement)

- Safety Guard provided with limit switch (to avoid accident )

- To in chance the mixing finger type baffle are provided centre of main body

- Material loading unloading charging drum arrangement provided with mechanical/ hydraulic trolley

- Internal finish 220 grits to 320 grits and outside matt finish 180 grits.

- Rotation specially designed high efficiency duplex chain drive

- Double Cone shape & slow speed of rotating gives continuous movement to the granules, result in good quality

- Easy for cleaning

- Simple design and minimum maintenance

- Capacity available in 10 to 6000 ltrs & 2 to 10ltrs for R & D models.

- Manual rotating facility with hand wheel for inching

Other Options Available

- Flame proof construction drive motor along with flame proof c. panel / starter

- Vacuum loading facility for material charging

- PLC with HMI

- VFD

Document

Documentation Like DQ, IQ, OQ, Manual and FAT provided with the machine

Liquid Manufacturing Plant

The Liquid Manufacturing Plant Are Ideal Tools For The Pharmaceutical Industry For The Production Of Oral Liquids. It Is Specially Design To Take Care Of Two Critical Factors Which Directly Affects The Quality Of The Liquid Minimum Man Handling Of Liquid Effective Cleanness During Manufacturing Needless To Say. It Also Provides The Benefits Of The Effectives Manpower Utilization. We Offer Liquid Syrup Manufacturing Plant Available In Various Batch Capacities From 100 Ltrs To 5000 Ltrs. It Provide With Sparkler / Housing Filter And Sparkler Filters For Final Filtration. Plant Is Provided With Interconnecting Piping With Pumps And Valves. To Top / Bottom Entry Motor Of Suitable HP Is Provided With Specially Designed Agitator As Per Our Clients Requirement

The Plant Consists Of

- Sugar melting vessel

- Manufacturing vessel

- Transfer pump

- Working platform

- Storage tank

- Inline homogenizer

- Online sugar syrup pre-filter (basket filter)

- Piping of complete plant

- Control panel

Salient Features:

- The Complate line is manufactured under cGMP standard

- All contact parts made of ss316/ss316L

- Entry of all propeller agitations is form bottom through a specially designed mechanical seal face.

- All pipes fitting are of ss316/ss316L seamless internally electro polished with silicon gaskets.

- Inline homogeniser will be provided as per clients requirement

- Zero hold up filter press gives crystal clear filtration.

- Automatic operation are ensured with PLC based control panel.

- Easy to assembly Fit and clean.

- Pressure gauge, safety valve & Air vent will be also provided

- Jacket for heating & cooling

- Heating by steam or hot water circulation.

- Welded flanged or hinged type cover.

- Integrated cleaning in place-CIP.

- The pump also discharge the product in the storage vessel.

- The entire plant can be operated by centralized operating panel by one operator.

- The sugar and water are load with vacuum system or by mechanical system or manually..

Optional:

- CIP Connection

- Load cell for online weighting

- Vacuum pump

- Inline homogeniser

- FIP constructions

- AC drive for variable speed

- The liquid manufacturing capacity available 100Ltrs to 5000Ltrs.

Fluid Bed Dryer

We Are Offering Our Client A Wide Range Of Fluid Bed Dryers. Which Are Available In Various Size And Specifications. Fluid Bed Dryer Is Designed To Introduce The Hot Air Steam At The Base Of The Product Container Which Is Filled With The Material. The Fresh Air Is Heated By Means Of Electrical Heater Or Steam Radiator . This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Rating Turbulence In The Product. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer. The Fluid Bed Dryer Are Most Suitable For Drying Granular, Crystalline, Coarse Or Similar Material In Pharmaceuticals, Fine Chemicals Dyes Food And Allied Products. Fluidized Bed Drying Process Is Controlled And Monitoring On Line Humidity Inlet Outlet Air. Fortune Fluid Bed Can Be Designed To Be Installed In High Containment Granulation Lines For Both R & D Labs Or Production

Salient Features:

- Mos-ss316/316L/304

- Online sampling port provided

- 65% open perforated air distribution plates with weave mesh

- Explosion Relief disc

- Uniform drying at low temperature..

- Minimum handling more hygienic

- Top Mount pneumatic cylinder (Directly coupled) Shaking (without wire rope system)

- Pneumatically operated inflatable seals provided for filter bag and product container sealing with pressure switches & FRL to ensure fail safe operation

- Fully automatic operation.

- Double wall PUF instigated AHU with PRE/MICRO V shape filters and cooling coil can be provided on demand on extra cost..

- Manually operated air dampers provided to control the inlet and outlet air flow

- Very fast processing time

- Easy to validate cleaning process

- Easy Scale up to higher capacity units

- Single scale up to higher capacity units

- Fully automatic bag shaking arrangement

- The capacity ranging from 5/10/15/30/60/120/150/200/250/300/350/500 kgs, with steam/ electrical heating facility

Control Panel / Pneumatic Panel.

- Panel board is fabricated from ss304 sheet the same can be provided electrical panel, or PLC based operation and pneumatic panel

- Temperature indicator

- Blower motor start/ stop

- Finger bag shaking timer

- Solenoid valves etc

- FRL

- Air pressure gauge

- Cooling timer etc.

Saftey Features.

- Positive ear thing device

- Solid flow monitor

- Explosion vent provided with rupture disk

- Ensure complete elimination of static charge

Optional:

- Flam proof motor

- PLC automated control system are available

- Electrically & steam operated available for heating

- Solid flow monitor valve.

- Telescopic cylinder

- Flam proof control panel

- Three piece design is also available in GMP model

- Extra container with trolley for more utilization of machine.

- A.C frequency drive for blower motor

- Differential pressure gauge or differential pressure trans meter a cross the air discharge bag. Inlet air filter and container sieve.

- Pneumatically operated butter value with actuator.

Application:

- Chemical

- Pharmaceutical

- Food Product

Storage Tank

A Storage Tank Is A Container, Usually For Holding Liquids, Sometimes For Compressed Gases (Gas Tank). Storage Tanks Operate Under No (Or Very Little) Pressure, Distinguishing Them From Pressure Vessels. Storage Tanks Are Often Cylindrical In Shape, Perpendicular To The Ground With Flat Bottoms And A Fixed Or Floating Roof. There Are Usually Many Environmentally Regulations Applied To The Design And Operation Of Storage Tanks, Often Depending On The Nature Of The Fluid Contained Within. Above Ground Storage Tanks Differ From Underground Storage Tanks In The Kinds Of Regulations That Are Applied. Storage Tanks Are Available In Many Shapes, Vertical And Horizontal Cylindrical, Open Top And Closed Top, Flat Bottom, Cone Bottom, Slope Bottom And Dish Bottom. Large Tanks Tend To Be Vertical Cylindrical, Or To Have Rounded Corners (Transition From Vertical Side Wall To Bottom Profile) To Easier Withstand Hydraulic Hydrostatically Induced Pressure Of Contained Liquid. Most Container Tanks For Handling Liquids During Transportation Are Designed To Handle Varying Degrees Of Pressure.

Features

- These Product are Durable, Robust and Cost effective

- Tanks & Vessels are used for storage of chemicals, solvents & any type of liquids

- We manufacture custom storage tanks for the chemical, pharmaceuticals and food processing Industries

- To ensure the product quality and compliance with customer specification, all of our fabricators. Tanks & Vessels can be fabricated in various designs and options such as shape, capacity and material of content. In shape i.e. vertical, horizontal, rectangular and capsule

- In capacity i.e. from 50 Ltrs to 15,000 Ltrs. In material of content i.e. SS 304, SS 316, SS 316L and Mild Steel

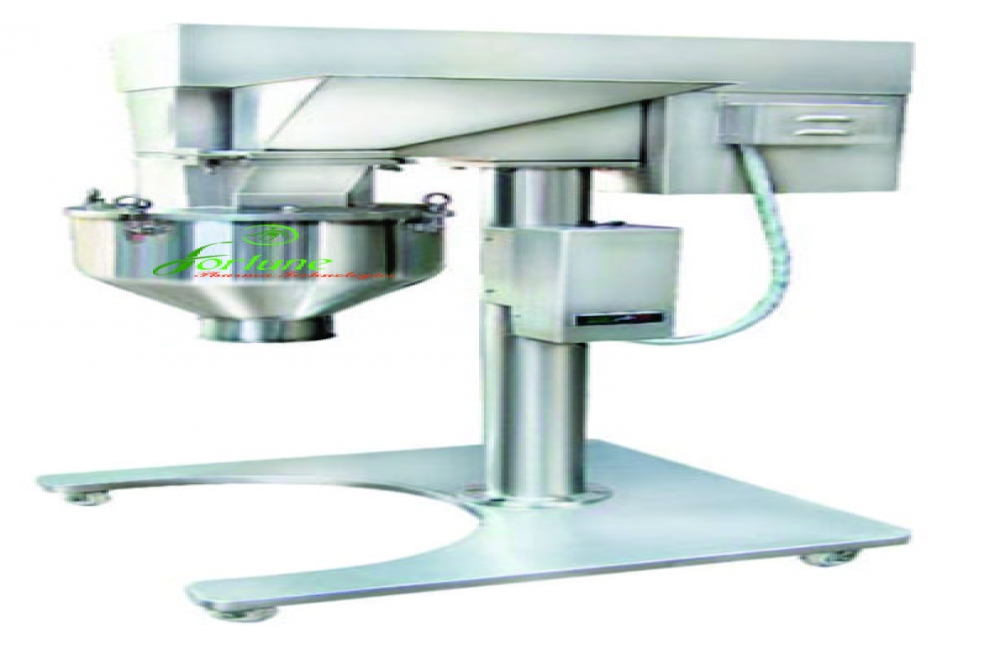

Rapid Mixer Granulator

Our Rapid Mixer Granulator Designed To Achieve Fast Dry Mixing Homogeneous Binder Distribution And Making Wet Granules In The Same Bowl. The Entire Process Is Fully Closed. Safe, Dust Free And Automatically Discharges The Materials. Rapid Mixer Granulator Is A Versatile Machine Developed For Mixing As Well As Granulation Of Ingredients We Manufacture Machines Meeting To The Highest CGMP Standards. Our Clients Can Avail This Rapid Mixer Granulator In Different Technical Options And Can Be Availed From Us At Most Affordable Prices. The Resulting Granules Are Of A Size And Density To Improve Flow And Compatibility For The Tableting Process.

Salient Features:

- Specially designed plain mixing bowl provided with counter-balanced lid-vent ,view-port and charging hole

- Main impeller consists of dual speed 750/1400 Rpm

- The chopper drive of the RMG. Consists of dual speed 1400/2800RPM the chopper has specially designed 3 blade the assembly in the rapid mixer granulator is mounted horizontally into the bowl

- Different models are available depending upon capacities

- Through the wall installation : minimum space required in GMP area

- Prefect cGMP design smooth covering no external tubing and piping allowing easy cleaning.

- Model available from 10ltrs to 1200ltr. Gross capacity.

- Manual or PLC controlled operations

- Anti-vibration mounting

- All contact part made from stainless steel ss316/ss316L/noncontact parts from ss304 M.S. with ss304 covered.

- All pneumatic components are of “festo” Janatics” make on client requirements.

- Equipment air and purging air control via differential air pressure switches.

- Platform & staircase ss Dimple plate

- Lid gasket silicon

- Base frame Ms. Sq. pipe with ss304 covering and frame top with ss304 chakkel plate.

- Bail in cleaning system for both shaft seals. .

Control Panel

- Panel board is fabricated from ss304sheet. The same can be provided electrical panel or PLC Based Operation.

- Auto / manual controls

- Indicator Lights.

- Ammeter / Voltmeter for both motors

- Controls for discharge opening / closing

- Air regulator & pressure gauge & Air filter

- Optionally a PLC based control panel can be provided

Safety Features:

- Limit Switch are provided on main lid and discharge valve inter locked with control panel for safe operation.

- Charging port with safety grill to prevent accidental contact of the operator moving parts.

- Both motors and discharge port piston are interlocked with main line air pressure switch to avoid accidental opening of discharge port to cause product loss in case of insufficient air pressure.

Optional:

- Flam proof motor with FLP push button

- Pneumatic systems for opening / closing of bowl Lid can also be provided

- VFD drive for speed variation of main motor and chopper motor

- Spray ball for inbuilt cleaming and spray nozzle for spraying of blinder.

- Co-mill also will be provided at discharge

- Water jacketed product container with temperature sensor for product

- Discharge provided on left or right side (as per granulation room layout) to suit clients requirements.

- PLC with touch screen

- Flam proof controls

Multi Mill

Multi Mill Is Widely Used For Wet And Dry Granulation Pulverization Etc, Of Pharmaceutical , Chemical, Bulk Drug Cosmetic, Colours, Dyestuffs, Food Production Etc. The Unit Consists Of SS Hopper, Processing Chamber With Beater Assembly, Motor Dol Starter, Three Speed Pulley, Screen And Study Body. SS Beaters Having Knife And Impact Edges Rotate Within A Selected Screen. The Material Is Feel In The Hopper And Milled Through Speed And Direction Of Beaters Could Be Adjusted Through Control Panel The Material Then Passes Through The Cylindrical Screen In Spiral Motion Which Helps Keeping The Temperature Low And Avoids Chocking Of Material During The Process The Material Is Collected In The Container Placed Under The Hopper.

Salient Features:

- All contact parts ss316/ss316L/ss304 available in standard and GMP model.

- All contact part can be easily and quickly dismantled

- Beaters and scraper blades are hardened and hard chrome plated.

- Machine is designed for continuous operation. Castors are provided for mobility of the machine.

- 12 Nos. beaters with knife edges & impact edges & 02 Nos. scrapper Blades.

- Reversible direction of blade rotation.

- Different size of screen/speed/number of blade/ Direction of rotation of blade can be selected.

- Wide range of ss perforated screens available

- Lab. Model also available

Optional

- Flameproof motor can be provided at extra cost

- VFD can be provided at extra cost

- Flameproof Electrical0s Panel can be provided at extra cost

- Different size of perforated sieve.

- Dry mechanical seal.

- Safe earthing system.

Technical Specification

Output Reduction 50 Kg to 200 Kg per hour depending on the product and size required Beater 12 nos. with knife and impact edges & 2 scraper blades Motor 3 hp, 2800 RPM, 415 V, 50Hz, 3 PH, AC Screen Area (mm) 495 x 135 (66825 sq. mm) Screen size: (I) Perforated 0.5 to 25 mm (II) Wire mesh 4 to 100 mesh Rotor Speed 750, 1500, 2300, 3000 RPM Dimensions (mm) 1230 (L) x 760 (W) x 1700 (H1) Rotor Assy. Dia 250 mm Net Weight (Kg) 250 Kg

Co Mill

Co Mill Is Used For Dry And Wet Milling/Size Reduction Of Wide Range Of Products. It Is Suitable For Stand Alone As Well As Online Milling.

Benefits & Highlights

Low speed design allowing for inherently gentle action on the product resulting in optimum particle granularity, low heat, low noise, minimal fines, consistent, high quality end product, can be used on heat sensitive products, high capacities, fully customizable to many different applications and process stream.

Advantages As Compared To Other Milling Equipment :

- The Output in Co Mill is very near to the size of the sieve used approx. 80% - 90% where as in Multi Mill it is 1/3 of the sieve used

- The Fines generated are on a lower side as compared to other mills

- Heat generation in Co Mill is comparatively very low as it works on forced pressure

- Other Mills have more of dusting as compared to Co Mill

- Output in Co Mill is more than any other mills

- Design is flexible as per your requirement.

Ribbon Blender

The Ribbon Blender Pharmaceutical Gives Best Result For Granules For Granules It Can Use For Pharmaceutical Food, Chemical And Cosmetic Products Etc. The Type Of Material Gets Sufficient Continuous Movement Due We Are A Prime Ribbon Blender Manufacture And Supplier From Thane Maharashtra. We Make Ribbon Blender According To The Client’s Specification As Needed. Our Granules Ribbon Blender Needs Low Maintenance And Has Low Power Consumption. Two Third Of The Volume Of The Blender Is Filed To Ensure Proper Mixing Products. Offered Ribbon Blender Machine Can Be Availed At Affordable Price. All Contact Part Made Of Ss316 Or Ss316L Quality Material Non-Contact Part Made Of Ss304 Or Cladded

Features:

- Discharge output via. Butter fly value. (Pneumatic discharge can be provided as per client requirement)

- To in chance the mixing Ribbon Buffle are provided centre of main body

- Internal finish 220 grits to 320 grits and outside matt finish 180 grits.dy

- Rotation specially designed high efficiency duplex chain drive/Direct Drive By Coupling

- Ribbon shape & slow speed of rotating gives continuous movement to the granules, result in good quality

- Easy for cleaning

- Simple design and minimum maintenance

- Capacity available in As per Client Requirements

Other Options Available

- Flame proof construction drive motor along with flame proof c. panel / starter

- Vacuum loading facility for material charging

- VFD

Automatic Tube Fill And Closing Machine

This Machine Is A High Technical Equipment Which Successfully Developed And Designed By Introducing Into Advanced Overseas Technology And Integrating GMP Requirement With Features Of Fair Structure It Adopt With PLC Controller Automatically Operating From Liquid Or High Velocity Material Filling Till Batch Number Printing (Include Manufacture Date) It’s An Ideal Equipment For Alutube, Plastic Tube And Multiple Tube Filling And Sealing In Cosmetic Pharmacy They Are Then Loaded One By On Into The Holders On The Turret. Tubes Have To Be First Manually Transferred From On The Turret. Tubes Have To Be First Manually Transferred From The Tube Box Into The Cassette On The Machine. The Machine Offers Automatic Warning (Audio-Visual Alarm Annunciation System) An Failure Or Abnormal Function.

Salient Features:

- Automatic tube loading system

- Auto tube orientation

- Combo model suitable for both aluminium and laminated/ plastic tube

- CGMP model

- PLC model (optional)

- Output 70 to 80 tubes min-for double head M/C

- Output 35 to 40 tubes min- for single head M/C

- Simple mechanism & operator friendly Machine

- No tube no filing device

- Lower maintenance require

- Automatic tube ejection

- Manually tube feeding

- Production counter available on control panel to indicate number of tube filling

- Tube cooling by water to circulation water outside tube for improve sealing quality

Technical Specification:

- Filling range 3GM to 250GM with change over

- Tube dia up to 25MM:- for double head

- Tube dia up to 45mm for single head.

Ointment Plant

Ointment manufacturing plant is an ideal tool for the pharmaceutical & cosmetic industries for the production of ointment cream, lotions, tooth paste and other emulsions and homogenizations. We manufacture quality ointment manufacturing plant which is made from superior stainless steel and a fully automatic no human contact to ingredients to ensure purity of ointment it is producing. The entire drive to the manufacturing vessel is provided from the bottom. That is the reason that bottom entry model is very useful for multiple product. Batches anchor design of agitator along with the W shaped with baffles imparts the contra rotary mixing Patten. Floating Teflon scrappers eliminates the risk of charring at vessel walls. It is fully equipped with sophisticated instrumentation & automation. PLC with HMI or Industrial Pc is provided along with the machine

Salient Features:

- Dual speed anchor agitator

- Hydraulic lid lifting for MFG vessel

- Double Cartridge type mechanical seal for main vessel

- Ergonomically designed anti skid working Platform With safety railing for better & safe operational movement

- All material transfer are done by vacuum pump or by transfer pump

- Minimum man handling of ointment.

- Specially designed stirrer with flexible Teflon scraper

- Minimum change over time

- Documentation: DQ, IQ, OQ provided

- Specially Designed inline filters provided to ensure proper filtration.

- Variable speed drive provided for main anchor stirrer assembly for different speeds

- Contact parts made out of ss316/ss316L quality material conforming to cGMP

- All pipeline are electro-polish from inside and joints are easy open able & fitting after cleaning

- Easy for loading and unloading

- Easy for cleaning

SPM Ointment Plants Consist The Following Equipment And Accessories

- Manufacturing vessel or Jacketed Planetary mixer

- Wax phase vessel

- Water phase vessel

- Storage vessel

- Vacuum pump

- Product piping

- Control panel

- Working platform with safety railing

- Interconnecting pipeline

- Material transfer pump to transfer material from manufacturing vessel or planetary mixer to storage vessel and storage vessel to ointment to Tube Filling Machine.

Optional:

- Load cells for batch weighting avoiding human error

- High level low level sensor

- PLC Based Control panel for Process Automation

- The ointment manufacturing plant/ cream manufacturing machine is suitable for manufacturing pharmaceutical ointment sterile preparation, cosmetic creams, Suspensions, gels, etc.

- Contra type agitator for Calcium base tooth paste

- Type of Models: Model : 50 100 250 300 500 750 1000 1500 2000 2500 Gross Volume Ltrs.: 65 125 315 425 615 925 1250 1850 2400 3000 Batch Size In Kgs. : 50 100 250 350 500 750 1000 1500 2000 2500

Starch Paste Kettle

The Starch paste kettle we fabricate and develop is a specially designed unit for application in pharmaceutical processing units. The tilting type arrangement ensures ease in uploading the paste into any container or vessel. It has a manual tilting arrangement with worm/worm-wheel arrangement. The demand of our offered starch paste kettle are easy to use. Sturdy in construction and require minimum maintenance. These starch paste kettle are mostly used to prepare starch, paste and binder solution for making granules. The kettle will be insulated with 50mm. thk. glass wool insulation and added With 16 SWG. SS304 sheet

Features

- Hemispherical design for proper mixing past

- Jacket provided with steam/ thermic/ fluid heating arrangement

- Anchor type impellar with scrapper design for proper mixing of paste

- Tilting arrangement for kettle is provided for discharge for paste

- Safe earthing system

- Driven via motor and gear box assembly mounted on top with Arm

- Operating panel provided with vessel

- Outside surfaces will be insulted with SS304 and surface will be polished to the mirror finished

- In compliance available -50Ltrs to 300Ltrs.

- Bottom discharge with flush bottom ball valve.

- All contact part made of SS316/SS316L as per CGMP standard.

Optional

- Flamproof Construction

- VFD to change the Rpm of Stirrer

- Digital temperature controller or digital timer.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.