FORTUNE PHARMA TECHNOLOGIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FORTUNE PHARMA TECHNOLOGIES

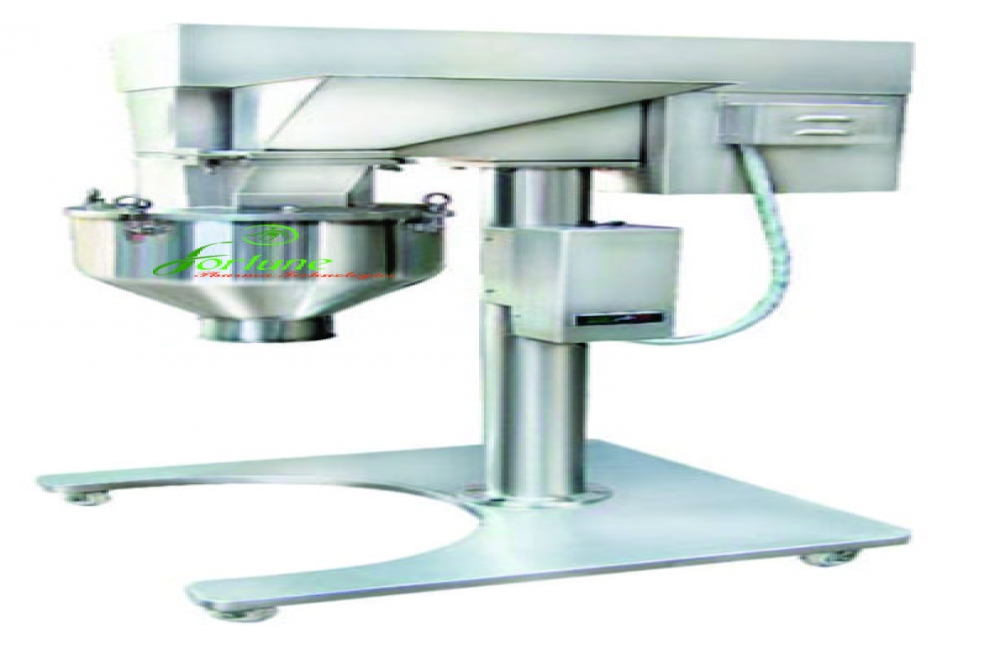

Multi Mill

Multi Mill Is Widely Used For Wet And Dry Granulation Pulverization Etc, Of Pharmaceutical , Chemical, Bulk Drug Cosmetic, Colours, Dyestuffs, Food Production Etc. The Unit Consists Of SS Hopper, Processing Chamber With Beater Assembly, Motor Dol Starter, Three Speed Pulley, Screen And Study Body. SS Beaters Having Knife And Impact Edges Rotate Within A Selected Screen. The Material Is Feel In The Hopper And Milled Through Speed And Direction Of Beaters Could Be Adjusted Through Control Panel The Material Then Passes Through The Cylindrical Screen In Spiral Motion Which Helps Keeping The Temperature Low And Avoids Chocking Of Material During The Process The Material Is Collected In The Container Placed Under The Hopper.

Salient Features:

- All contact parts ss316/ss316L/ss304 available in standard and GMP model.

- All contact part can be easily and quickly dismantled

- Beaters and scraper blades are hardened and hard chrome plated.

- Machine is designed for continuous operation. Castors are provided for mobility of the machine.

- 12 Nos. beaters with knife edges & impact edges & 02 Nos. scrapper Blades.

- Reversible direction of blade rotation.

- Different size of screen/speed/number of blade/ Direction of rotation of blade can be selected.

- Wide range of ss perforated screens available

- Lab. Model also available

Optional

- Flameproof motor can be provided at extra cost

- VFD can be provided at extra cost

- Flameproof Electrical0s Panel can be provided at extra cost

- Different size of perforated sieve.

- Dry mechanical seal.

- Safe earthing system.

Technical Specification

Output Reduction 50 Kg to 200 Kg per hour depending on the product and size required Beater 12 nos. with knife and impact edges & 2 scraper blades Motor 3 hp, 2800 RPM, 415 V, 50Hz, 3 PH, AC Screen Area (mm) 495 x 135 (66825 sq. mm) Screen size: (I) Perforated 0.5 to 25 mm (II) Wire mesh 4 to 100 mesh Rotor Speed 750, 1500, 2300, 3000 RPM Dimensions (mm) 1230 (L) x 760 (W) x 1700 (H1) Rotor Assy. Dia 250 mm Net Weight (Kg) 250 Kg

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.