FLASH POINT EQUIPMENTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FLASH POINT EQUIPMENTS P.LTD.

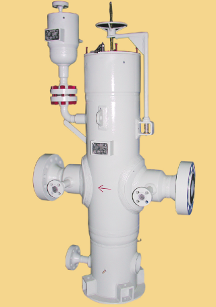

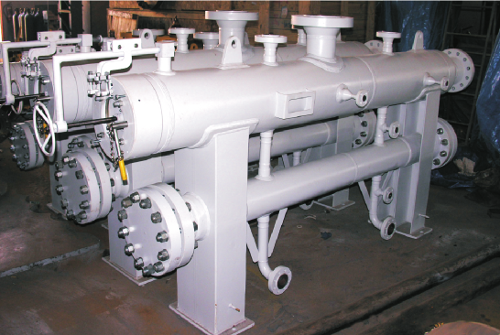

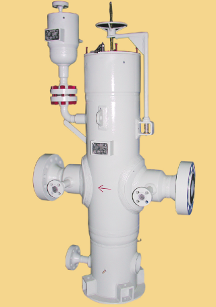

Fabricated Basket Strainers With Air Eliminator

Nominal shell size : 6" NPS to 72" NPS

• Design Pressure : Class 150, 300, 600, 900, & 1500

• Design Temperature : (-)46 Deg.C to 140 Deg.C

• Filter Elements : Cylindrical stainless steel cleanable and reusable Mesh elements reinforced by perforated sheets and caps at both ends Standard basket sizes are 100/140/ 160/ 195/250mm OD X 400/800/970mm long.

• Filtering Sizes : 10/20/30/40/60/80 wire Mesh or wedge wire screens

• Shell Closure Elements : Choice of quick opening closures (Flash Point SEG4LOCK) or bolted covers with davit.

• Filtering Efficiencies : Typically 99.8% of all solid particles larger than the opening size of the strainer mesh will be retained inside the strainer basket.

• Air Venting Options : All types of strainers can be fitted with automatic air vent AV-125 either internally or externally.

• Type Application Details : For most applications, vertically installed Basket type FAB-STR/ FAB-SAE are used. For low pressure drop and where access for basket removal is available below or sideways. "Y" pattern strainer type YFAB-STR is used. Where uninterrupted operation is desired, Duplex Strainer with changeover valves type FABDX-STR is used. Special materials for construction of internals. Nozzle configurations as per customer requirements. Special external & internal coating.

• Certification: EN 1020422004 Type 3.1 or 3.2, ASME "U", "UZ" Certi?ed, CE/PED Certified, NR-13 certified, AS-1210, ABS/DNV class certified.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.