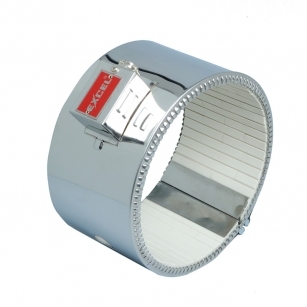

Ceramic Jacketed Heaters

Ceramic Jacketed Heaters are EXCEL’s premium product since three decades

Especially to heat the cylinders (barrels) on all types of plastic (s) processing machinery

The key to the ceramic – jacketed heaters is its superior design to save power

Outer insulation jacket conserves energy

Up to 40% of power consumption reduced

Maximum watt density = 50 Watts/square inches

Note: In case where high watt densities are required, it is important that all heaters should be used with appropriate, approved and precise temperature control/sensor device(s)

Maximum sheath temperature up to 800˚ C