EMCOLITE ULTRASONICS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to EMCOLITE ULTRASONICS

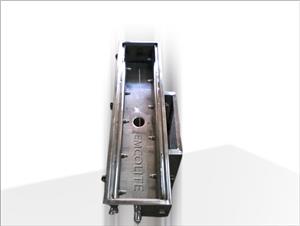

Automatic Barrel Cleaning System

|

Single Stage Ultrosonic Vapour Degreasing System

- Appropriate degreasing solvent is poured in ultrasonic chamber up to level indicated.

- The Job is Loaded on a basket or any other fixture for cleaning. Heaters are switched on to achive set tempreature.

- The loaded basket or fixture is lowered in the chamber and ultrasonic timer is switched on for a minute or so, Job is then raised for vapour degreasing and through cleaning is achieved.

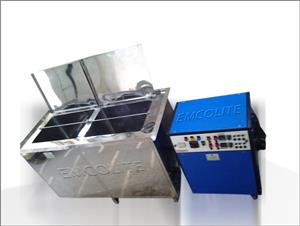

Two Stage Ultrosonic Vapour Degreasing System

This consist of two chambers such as ultrasonic chamber and vapour degreasing chambers Degreasing solvent is poured in both the chambers and electrically heated. The temperature is adjusted by thermostats. The job is loaded on basket or fixture and immersed in ultrasonic chamber for ultrasonic cleaning and then transferred to vapour degreasing chamber.

High Degree of cleanlines can be achived.

Three Stage Ultrasonic Vapour Degreasing System

When degree for contamination is more and heavy production is desired, third chamber as pre-cleaning chamber is necessary. The degreasing solvent remains same for all the three chambers. Solvent is electrically heated. The job is loaded on basket or fixture and immersed in pre-cleaning chamber first and subsequently in other two chambers.

Water Base Single Stage Ultrasonic Cleaning System

Appropriate liquid is poured in the tank for removing specific contamination. Heating if desired is also incorporated. The Job is loaded on jigs. Fixtures, Wire, Baskets or any other convenient method and immersed in tank for prescribed time. Single stage ultrasonic cleaning system is useful with Neutral or Alkaline liquid. Acidic solution to be used with special arrangements.

Jwellery Cleaning Machine Digital Ultrasonic Cleaner

|

Immitation Jwellery Cleaning System

|

Immitation Jwellery Cleaning Systems

|

Jwellery Cleaning Machine

|

Jwellery Cleaning Machine Fourty Ltr

|

Jwellery Cleaning Machine Six Ltr

|

Jwellery Cleaning Machine Nine Ltr Separate Type

|

Online Wire Cleaning System

|

Manual Barrel Cleaning System

|

Multi Stage Ultrasonic Cleaning System

- Multi-stage ultrasonic cleaning system may contain following stage.

- Water based ultrasonic tank

- Water based Swil tank.

- Alkaline solution based ultrasonic tank.

- Water based ultrasonic tank.

- Water based Swil tank.

- Vapour Degreasing chamber.

- Acidic Solution based ultrasonic tank.

Water Base Two Stage Ultrasoni Cleaning System

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.