DYNEMECH SYSTEMS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to DYNEMECH SYSTEMS P.LTD.

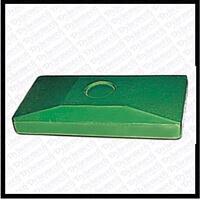

Insulation Plates

Dynemech offers ANTI VIBRATION SHEETS made from high grade synthetic composite material. These sheets have different load capacities and are available in different natural frequencies to suit various industrial applications. These are resistant to water, oils, lubricating oils, fuels etc. used in the shop floor. Each sheet has defined stress value and can be placed directly under the machine as per the weight of the machine and no. of mounting positions. These plates will not deform plastically, if the weight of machine

Screw Support Mounts

Dynemech Screw Support Mounts are designed for industrial machinery that require levelling and vibration isolation and reduction. These circular mounts are placed between the machine feet and the floor. The machine feet rest on top of the circular mount and vibrations are isolated based on the vibration frequency generated by the machine and natural frequency of the screw support mounts.

All Screw Support Mounts have a specialized elastomeric insulation plate at the bottom which are tuned to different natural frequencies for different applications provides excellent vibration isolation. Different models of Vibration Isolation Mounts are available depending on whether the machines:

Anti Vibration Wedge Mounts

Wedge Mounts - Series DF

Dynemech wedge mounts are designed for industrial machine tools that require precision leveling. This 3-piece wedge mount has an adjustable bolt which moves the center wedge between top and bottom stationery wedges to provide lift, to the top wedge. Anti-Skid plate is provided on the top wedge therefore, machines are installed as free standing. Large supporting surface ensures solidity and rigidity. Vibration reduction is possible through assembling respective Dynemech insulation plates.

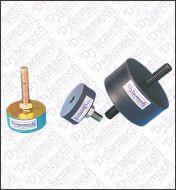

Studmounts Or Silent Blocks

Stud Mounts Series DS

Dynemech Stud Mounts Series DS are highly effective and compact vibration dampers for a varity of applications like- Compressors, Pumps, ID & FD fans, Motors, Machine tools, Gensets, Air Conditioners, Measuring and Testing Equipment / Instruments, Material Handling Equipment, Laboratory etc. These mounts can be used for load applications in both compression and shear.

Leveling Mounts

Dynemech Machine Base Mounts Series SL

Dynemech Machine Base Mounts Series SL is used for light to medium weight machines suited to levelling screw support or having tapped hole in the base. These are suitable for placing in the pocket of the machine base.

Dynemech Machine Base Mounts Series SLS, developed in stainless steel finds application in pharmaceutical, food and beverages processing and packaging units, medical equipment manufacturing and chemical processing industries. Provide vibration isolation with complete hygienic seal and corrosion resistance.

Rubber Air Springs

Rubber Air Springs - Series DRAS

Dynemech rubber air springs Series DRAS provide highly effective insulation of machines against low frequency vibration / impact. The element offers a vertical natural frequencies between 2.5 to 6.0 Hz (depending upon the pressure required to support the load). The component has vertical to horizontal stiffness ratio of approximately one. Suited for both active and passive vibration control.

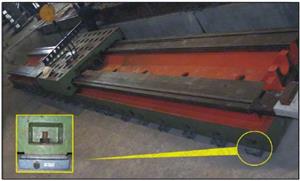

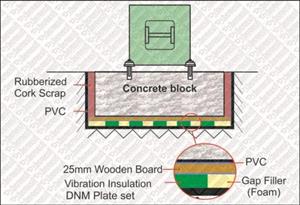

Foundation Isolation

Isolated foundation for active vibration damping for power presses, forging hammers, engine test rigs, and passive vibration isolation of machining centres, grinding machines, measuring & testing equipments, laser cutters and microscopes.

The ISOLATED FOUNDATION is required to reduce both active and passive vibrations. Vibration isolation mountings are required to reduce the transmission of vibration and shocks.

Anti Vibration Pads For Honing Applications

Honing is a metal removal process used after casting, sintering, drilling, boring, or reaming to obtain precise bore dimension, geometry (cylindricity, roundness, straightness, and taper) and surface finish. Though with the development of precision machining and ultra precision machining technology, machining precision demands to achieve sub micron level have increased, chatter is still a problem during grinding which affects surface quality directly and reduces productivity. It is more serious in high precision honing process in which a small vibration would make the size or surface roughness of proposed part poor, leading to rejections.

In general honing the movement of the honing head is the synthesis of rotation movement and reciprocating movement whose trajectory is a spiral curve with up and down movement in close tolerances. With them numerous mechanical structure, rotating and revolving parts with different mechanisms working in compression, stress and torsion in a machine, lead to arousal of vibrations during the honing process.

Vibrations may also travel from external environment to Honing Machines disturbing surface finish and accuracy of the job. Dynemech low natural frequency isolators damps most of the incoming vibrations and allows smooth operation.

Vibration isolation is imposed to separate a dynamical system from its environment by means of isolator/pad/mounts which has a considerably different natural frequency, compared to the forcing frequency of the applied force.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.