DYNEMECH SYSTEMS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to DYNEMECH SYSTEMS P.LTD.

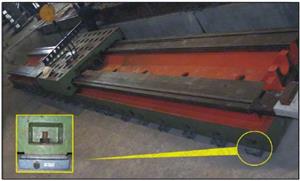

Anti Vibration Pads For Honing Applications

Honing is a metal removal process used after casting, sintering, drilling, boring, or reaming to obtain precise bore dimension, geometry (cylindricity, roundness, straightness, and taper) and surface finish. Though with the development of precision machining and ultra precision machining technology, machining precision demands to achieve sub micron level have increased, chatter is still a problem during grinding which affects surface quality directly and reduces productivity. It is more serious in high precision honing process in which a small vibration would make the size or surface roughness of proposed part poor, leading to rejections.

In general honing the movement of the honing head is the synthesis of rotation movement and reciprocating movement whose trajectory is a spiral curve with up and down movement in close tolerances. With them numerous mechanical structure, rotating and revolving parts with different mechanisms working in compression, stress and torsion in a machine, lead to arousal of vibrations during the honing process.

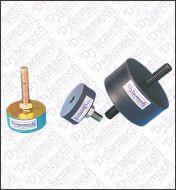

Vibrations may also travel from external environment to Honing Machines disturbing surface finish and accuracy of the job. Dynemech low natural frequency isolators damps most of the incoming vibrations and allows smooth operation.

Vibration isolation is imposed to separate a dynamical system from its environment by means of isolator/pad/mounts which has a considerably different natural frequency, compared to the forcing frequency of the applied force.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.