D.P.PULVERISER INDUSTRIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to D.P.PULVERISER INDUSTRIES

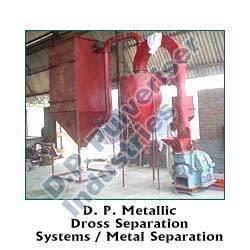

Metallic Dross Separation System

The D. P. Impact Pulveriser is modified for metal dross separation. The metalic dross to be separated is crushed in the crushing chamber, care is taken during crushing, that the pure metal is not crushed into very fine particles size, as this metal is very difficult to recover. In the crushing chamber, a suitable door is provided for the separated metal to get discharged. The quality of this metal (i. e. percentage of pure metal) is in form of granules and oxides, depend on the percentage of pure metal in the dross. If the dross is of high metal content, then the discharge through the door is of high purity. If the dross is of low metallic content then, with the metal granules there is a small percentage of oxides. This mixed metal with oxides needs to be sieved.

The whizzer classifier obstructs the pure metal granules to pass into the blower, however some particles escape from the whizzer and enter into the blower. This material from the blower is taken to a pre cyclone, to remove all the pure metal granules entering into the cyclone, so the material collected in the cyclone is only oxides. The outlet of the cyclone is connected to a dust collector, so all fine oxides are collected in the dust collector.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.