D and M ENTERPRISES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to D and M ENTERPRISES

Ucan High Performance Injection Moulding Machine

Excellent design features make U CAN machinery very versatile to use high productivity, durability, and easy to maintain

UCAN utilises key components from the world renowned manufacturing of Servo system, Microprocessor controller hydraulic systems electrical parts and lubrication parts

The design utilise very sturdy mechanical components.

Ability to process all types of Thermoplastic and Thermoset materials with wide range of Screw and Barrel for each application

Machine range from 90 Ton to 1650 Ton and Immediately available range from 90Ton to 320Ton

U CAN machine offers the best combination of ROI (Return of Investment) and COW (Cost of Ownership)

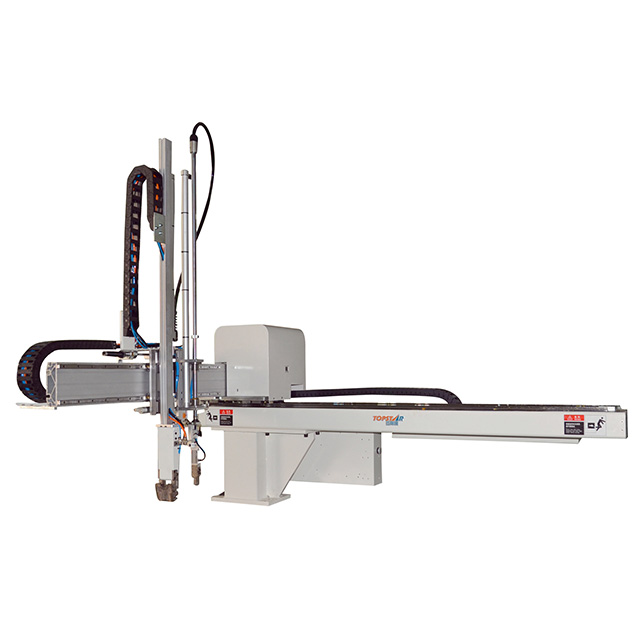

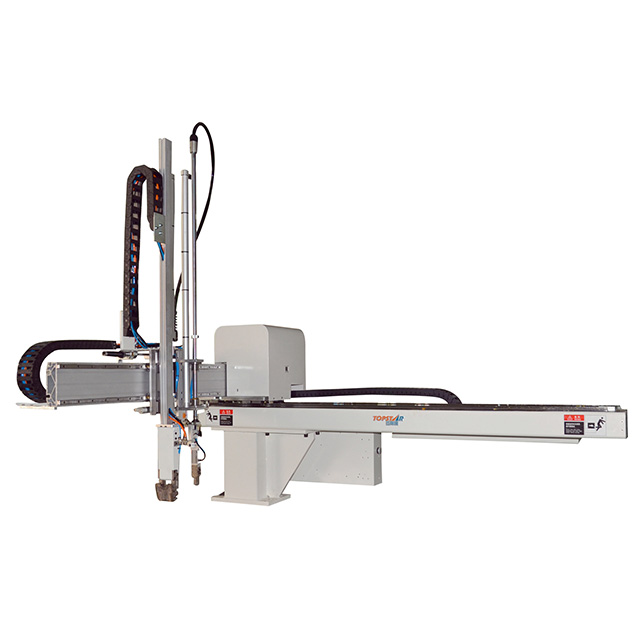

Three Five Axes Ac Servo Driven Robots

Three/ Five Axes AC Servo Driven Robots are extensively applied to horizontal plastic injection machines from 75~3000T which are mainly designed for rapid and precise removal on strict demands of good appearance of finished products and spruces. There are two types of arms – single stage and telescopic. The vertical strokes for single stage are 700/800/900 and for telescopic are 800/900/1000/1100/1300/1500/1700/2000mm. Full AC servo motors are driven on three axes (traverse /crosswise /main arm) and fiveaxes (traverse /crosswise & vertical for main arm & sub arm), take-out at super high-speed 1.4 sec and dry cycle time within 5.6 seconds. All linear movement are controlled by servo driven control systems to cooperate with high rigidity structure of linear guide rail for realizing high precise take-out and accurate repeatability.

Single Axis Ac Servo Driven Robots

Single Axis AC Servo Driven Robots are extensively applied to horizontal plastic injection machines ranging from 50 ~1800T which can take out the runners, runner and finished products from the mold of plastic injection molding machines. There are two types of arms-single stage and telescopic. The vertical strokes for single stage are 600/800 and for telescopic are 600/800/900/1000/1200mm. The arms move stably thanks to two sections of double speed structure. The traverse movement is driven by high performance AC servo motor. With different requirements of products, robot can work with various grippers and jigs to realize stable & perfect take-out products from mold by quick- descent of removal of products and slow -descent to place outside.

Spruce Picker

Etensively applied to horizontal / vertical plastic injection machines ranging from 50T~ 250T which can rapid take out the runners, runner and finished products from the mold of plastic injection molding machines, and place runners or runner into beside-the-press granulator for recycling immediately.

Industrial Robot

Topstar Industrial robots are widely used in welding, stacking, punching and other aspects of industries. multi-axis robot posture structure expands the freedom, without interference; the operating characteristics of high-speed, improves production efficiency; the best means of improving the structure of the welding quality. Universal high-speed robot is also applicable to arc welding; compact, slim design saves more space.

Chiller For Injection Moulding Machine

Feature

To adopt imported superb compressors and pumps to ensure safe & quiet running , power saving and durable service life.

To employ microcomputer with easy operation which can control temperature within ±3? to ±5? precisely.

Unique design for condenser and heat- dispersion unit result in excellent heat-exchange effect.

To equip with electrical current overload protection, high & low-pressure switch, electronic timer delay safety device. It will alarm to display faulty while any malfunction occurs.

To adopt with internal 304 stainless steel insulated water tank with durable service life for easy cleaning & maintenance.

Complete safety devices including power reverse phase & power short phase and anti-freeze protection.

Ultra low temperature type of chillers can reach below -15?.

Chillers for anti-alkaline & anti-acid type can be customized.

Conveyor For Injection Moulding Machine

The workbench is made of PVC material which can protect the external appearance of products.

Conveyor speed can be adjusted freely from 0~6m/min, operate easily and use conveniently.

It adapts universal castors with brake which can fix and move easily.

It is not only can realize automation to work with robot by connecting peripheral signal but also can work independently.

The TBA and TBL Series adjusted aluminum alloy frame which the height can be adjusted according to requirements.

Customized spec are available according to customers’special requirement.

Thermoset Injection Moulding Machine

Vertical mold clamping and injection, small footprint and high degree of precision. This Thermoset Injection Moulding Machine is ideal for injection of medium and small products with inclusions.

Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for production of thin items.

Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation.

Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects.

Thermoset Injection Moulding Machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production.

There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Vertical Injection Moulding Machine

Description / Specification of Vertical Injection Moulding Machine

We are involved in offering a wide range of Vertical Injection Moulding Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Vertical Injection Moulding Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Tgm Middle Speed Granulators

Feeding hopper employs double layers of stainless steel with superior sound-proof, durable structure & excellent appearance.Less powder, low noise, low consumption.This unit is driven by low speed motor ( 150 rpm). It can granulate detective parts into well-proportioned granules.Blades are made of SKD-11 with long service life.Rapid changing blades & screen design, easy maintenance.It is not only suitable for granulating rigid engineering plastics but also soft plastics.Safety protection device to comply with safety conformity, stable and reliable function.

Tgl Series Low Speed Sound Proof Granulators

As Low Speed Sound-Proof Granulators are non-mesh slow speed plastic recycling units with 25~30 rpm which specially designed with teeth cutters for crushing various defective products made of rigid plastics and brittle plastics such as PC, nylon, ABS and so on. All these models are characterized with low speed & high torque, low noise, less powder pollution, easy operation, granulating in even, no-overheating in operation and long service life.

Tto Series Oil Type Mould Temperature Controllers

Description / Specification of Tto Series Oil Type Mould Temperature Controllers

We are involved in offering a wide range of Tto Series Oil Type Mould Temperature Controllers to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Tto Series Oil Type Mould Temperature Controllers. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Hopper Receivers

Features:

Stainless steel construction used byER/FSR series for ensuring material free and for all structural by SR/CSRseries from contamination that working with detachable autoloaders.

Mechanical stainless flap fitting onER/SR/CSR series that need not to be adjusted according to different material.

With hopper receivers and bases arelocked by hinge, FSR/SR/CSR series is easy for dismate.

A diaphragm valve fitting on CSR seriesif several central hopper receivers want to share same blower for centralized feeding system.

FSR series is particularly designed foroptic product use for reducing power to cause any defects for enhancing productively qualities.

Autoloaders equip with photo sensors which are mounted onto the feeding port of IMM ;autoloaders equip with proximity switch which are mounted onto the hopper dryers

To adopt glass tube with photo sensor(static capacity detection)for precisely detect material conveying

To be fitted with stainless screen for easy filtering dust.

Tal Series Detachable Autoloaders

Description / Specification of Tal Series Detachable Autoloaders

We are involved in offering a wide range of Tal Series Detachable Autoloaders to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Tal Series Detachable Autoloaders. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Tcdh Series Compact Dehumidifying Dryers

Description / Specification of Tcdh Series Compact Dehumidifying Dryers

We are involved in offering a wide range of Tcdh Series Compact Dehumidifying Dryers to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Tcdh Series Compact Dehumidifying Dryers. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Tdls Compact Drying Auto Loaders

PET resin drying is the first step to have good quality bottles. Moisture must be taken out before injection. We always recommend to use dehumidifier which recycles heat to use energy wisely and to get PET dew point to -40°C or blow so that PET exhibits its optimum nature.

Tgp Series Powerful Granulators

Description / Specification of Tgp Series Powerful Granulators

We are involved in offering a wide range of Tgp Series Powerful Granulators to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Tgp Series Powerful Granulators. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.