CHETHAN ENGINEERING SERVICES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CHETHAN ENGINEERING SERVICES

Milk Processing And Packaging Plant

We provide Milk Processing & Packaging Plant that is widely used in dairy applications. These are manufactured using quality components, and quality tested at all parameters to ensure that the range is flawless. Known for their easy installation and maintenance, these plants suit the varied needs of our clients.

Chilling Centers

Our range of chilling center is manufactured using the latest technology to ensure that temperature can be brought down to the desired level easily & conveniently. High grade raw material is used to manufacture these chilling centers, which ensures dimensional accuracy, corrosion resistance and high durability. In order to ensure maximum utility to the clients.

Instant Milk Chilling Units

India is the largest milk producer in the world but only 20% of its milk production is being processed. In order to boost their milk procurement, many dairies have setup societies or collection centers in the rural areas. This has assured a remunerative price and market support to the producers. The traditional system of milk collection by the Dairy Cooperative societies included mainly to accept milk by volumes, carrying out fat testing and entering the fat and SNF data manually in the registers.

Milk By Product Plant

Leveraging on our extensive experience, we provide turnkey services for milk by product plant. These plants have capacity to handle 1k-5 lacs liters per day. The working principle lies as milk is received in a dump tank from the road milk tankers and is chilled upto 4ºC in chilling unit. Further, the chilled milk is pasteurized in a milk pasteurizer and the cream is alienated from the milk, using a cream separator to get skimmed milk.

Brewery Plants

Backed by a team of experienced and talented workforce, we are offering trusted services for brewery plants. These plants are fabricated using high grade raw material, which is sourced from reliable dealers. These are stringently tested by our highly qualified quality controllers to bear the impact of heat, cold, vacuum and pressure. Even the exterior of the tank is sturdily constructed to withstand with the adverse climatic conditions and to offer a longer service life.

Desuperheater

We have come up with Industrial Refrigeration Plants, that are made using latest technology and machinery. These plants are ideal for low temperature applications. Manufactured to accommodate varied refrigeration demands, these are available with many digitalized features such as Condenser, Evaporator, Controls, Instruments, Microprocessor Controller etc. for smooth and easy operations. These plants are also tested on quality parameters to ensure maximum satisfaction to clients.

Glycol Chilling Systems For Brewery

We have come up with a wide range of highly efficient Glycol Chilling Systems that is playing an important role in Brewery. These systems are inbuilt with advanced features like Power Pack, Trunk Line, Installation Equipment, Replacement Parts and more that helps in easy processing. These systems find application in concrete water batch cooling, extrusion water bath cooling, lasers CNC Lathes, injection Molding Equipment, sputtering Systems, vacuum Systems, turbo Molecular Pumps etc. However, these systems can also be customized as per the demands and specifications of our clients.

Cold Stores

With our years of experience, we are offering trusted services for cold stores that can be installed where fruits, vegetables or any other perishable items are required to be stored. It can be used to store other perishable products, such as milk and milk products. These cold rooms can be customized in various sizes and technical specifications to suit various requirements of the clients.

Beverages And Juice Processing Plant

We are proficient in designing and installing different fruit juice processing plants. We offer services for these processing plants that are provided on a turnkey basis with a series of machines for hygienic extraction and packaging of pure juice. The juice can be filled in PET plastic bottles by means of a hot filling system and then placed in cartons for bulk packing.

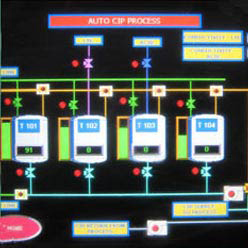

Process Automation

We are offering trusted services for process automation systems that are used by various industries like chemical industries, pharmaceutical and FMCG industry. The process automation system designed and installed by us uses the best available spare parts like conveyor belts, motors and control panels. As these systems are been designed and customized according to the process adopted at various industries therefore the design discussion is very difficult at this platform.

Vacuum Pouch And Bag

Modified Atmosphere) packaging pouches, Non-vacuum, Gas Flush Pouches

V Vacuum pouch offers extensive range of high barrier PA/EVOH-based 9, 7, 5 layer co-extruded barrier vacuum packing, gas flush and MAP Pouches These pouches are available in various sizes, have great strength and high clarity, and provide additional protection against oxygen & moisture. Available in various barrier levels (high, medium and low), VVacuum pouch is uniquely suited for producing large vacuum pouches & bags used in vacuum, gas flush and MAP applications for food and non-food services for retail industries & industrial usage.

Bulk Bags Liner

Specific customised liner bags for bulk packaging from Vishakha

VBulk Bags Liner offers wide range 9, 7, 5 layers PA/EVOH based high barrier film offers customised bag liners for bulk packaging. These are made to provide high-strength and are suitable for dry or liquid bulk packaging for big bins liners, Flexible Intermediate Bulk Containers (FIBC), container liner, drum liner, etc. With solutions from poly films to nine-layer co-extrusions, packaged material is protected from a range of contaminants such as dust, moisture, oxygen and/or chemicals.Vishakha also holds the expertise to provide customized solutions with varied option in terms of Large Gusseted capabilities, specialty formulations and sizes.

Food or Non-food product

Abrasives products

Biohazard bags

Fruits and vegetables

Chemical collection & transport bags

Compounds packing

Drum or box liners

Dust covers

Pharmaceuticals

Powdered products

Resin liners

Metal products

Oil packaging

Bulk process food liners

Bulk Agri-food transport

Bag-in-box liner

(E.g. tea, coffee beans, soya beans, pulses, rice, wheat, dried nuts & fruits)

Inner Bulk Liner

VInner Bulk liner

offers wide range 9, 7, 5 layers PA/EVOH& 3 layer inner liner Suitable for food as well as non-food applications, these barrier inner liner bags stand above the rest when it comes to a perfect match of quality, performance and cost efficiency too.

These bags can be used in multilayer paper, woven sake, corrugated box or big multilayer bags. Another feature is that these PA/EVOH based barrier liners can be hermetically sealed. As the bags are tough and puncture-resistant, they possess a lot of resistance against tough handling and are ideal during shipment and storage as well.

The inner bulk liners have strong leak-free sealing, and prove to have a strong barrier against moisture, oxygen pests and outside contaminants. They are strong, dependable, and maintaining freshness & great taste for long time. One more advantage is that they offer uniformity for more secure stacking, and are available in a wide range of sizes.

Thermoforming Films

V Thermo Forming,

offers PA/EVOH based 9, 7, 5 layer Co-extruded Flexible barrier film for thermo forming. This packaging solution has excellent formability, which makes it the optimal solution for deep draw applications. These forming films have a highly glossy appearance and superior aroma. VThermo is available with suitable for ‘easy peel’ property film and a wide range of thicknesses suitable for various drawing depths. These forming films ensure optimal performance with all other types of automatic thermoforming machines

V Thermoforming films are ideal for a varied food and non-food products like soft/hard cheese & dairy product, meat, poultry, fish & marine products, vegetables & fruits dried fruits & nuts, bakery products, ready meals (burger, pizza, eggs), chocolate bar & sweet welding rods, health care products, medical devises (syringes, surgical items) & much more.

Top Lid Film

VToplidding Film, has a range of high performance PA/EVOH based 9, 7, 5 layer Co-extruded Flexible barrier film for Top Web & MAP Tray Lidding Film, Flow pack Application. These high barrier films are ideally suited as lidding films on ready-made trays, as well top webs on all thermoform-fill-seal lines. This technique adds an advanced barrier layer that maintains product freshness while optimizing its shelf-life.

This film has great properties like easy peel and anti-fog. Available in high, medium and low barrier, this film can be used with different substrate types, including PE, PP, PS, PET, Aluminum and more. Your products’ will look great as VToplidding has a great glossy appearance and it is available in printed, unprinted, natural, tinted and pigmented films.

It is ideal for food and non-food products like cheese, dairy product, meat, poultry, fish & marine products, vegetables & fruits, dry fruits & nuts, bakery products, ready meals (burger, pizza, egg, etc), chocolate bar & sweet, welding rods, health care products, medical devise (syringes, surgical items, etc) & many more.

Lamination Film

Roll Stock for Lamination Film and Freezer Film

VLamination Film, offers 9, 7, 5, 3 layer CO-extruded Lamination films for adhesive, thermal lamination & other applications. These multi-layered, corona-treated films are also designed for lamination using any type of adhesive. These Co-Extruded thermal laminated films are available in a wide range of configurations, including different types of sealing layers, and anti-fog properties.

Vishakha Polyfab’s high-strength barrier film is strong against oxygen and moisture, and it is a clear, transparent film unlike the alternate aluminium film. It is available in a great range of material like PA, EVOH, PP, MPE, PE & Much more

Shrink Wrap Film

Perfect packaging solutions for your product's precise needs

VShrink Wrap Film

, Vishakha Polyfab also provides shrink wrap films and pouches for food and non-food industries. The company has developed a special LL/ LDPE based high quality shrink film, which is a world class standard packaging solution ideally suitable for packing wide range of products at an economical cost.

Importance of Shrink Film against corrugated packaging

At a time when conservation of the environment is a very critical issue, the recyclable shrink films come as a great solution. These films are also manufactured using eco-friendly recyclable materials. It proves to be a much better option against corrugated packaging, As it is light, the shrink films also help you save huge amounts in transport and freight.

Vishakha – the ideal provider of shrink films

Vishakha is the most advanced and superior provider of packaging solutions in India. Not only do we source the best of raw materials from across the world, we also gain the expertise to apply the right formulation for manufacturing. Vishakha also possesses a state-of-the-art machine specially designed for and totally dedicated to shrink film production.

Health Care Packaging

Medical Devices, Pharmaceutical & Hygiene products)

VHealth Care Packaging, offers the most technologically advanced 9, 7, 5 layers PA/EVOH based high barrier Co-ex film for medical packaging. Acting as the ideal barrier against oxygen and moisture, these films are made from a combination of many different materials to produce structures that enhance performance and offer great protection and safety.

The wide product range that Vishakha Polyfab offers for healthcare products includes thermoforming films, Lidding films, pouches, high barrier film, vacuum pouch pack, barrier liner, over-wrap film, high barrier film for lami-tube and sandwich laminates with high barrier film.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.