BELMARK INDUSTRIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BELMARK INDUSTRIES

Bow Roller

Bow roller is supplied with mounting brackets, which could be either wall mounting or foot mounting. The bow Expander Rolls consist of bowed shafts, sealed ball bearings, abrasion resistant sleeve and metal segments. These are widely used as wrinkle removing devices in various industries and are available in various dimensions. The rolls are also supplied with gear box and mounting brackets which can either be Foot Mounted or Wall Mounted. Bow Rolls are available in rubber surface, hard chrome surface and also Teflon covering for non-sticking applications. Hard chrome surface Bowed Roller is used where speed is more than 300 meters per minutes. If the speed is more, the bigger diameter is used to reduce the rpm of the roll.

Bow roller works only when there is proper lead-in and lead-out distance and kept in proper warp angle with web material. To make such warp angle adjustment all rolls are supplied with bow angle adjusting worm-worm wheel gearbox with hand wheel and counter pedestal bearing block. By use of this it is possible to adjust the bow angle at 360 degree warp angle. When the Roll get maximum wrinkle removing, stop the bow angle adjusting and put the roll on bow locked position. Do not make any change in the bow setting bow warp angle with web materials is set. On shaft bow position is indicated by an arrow showing the bowed position of the Roll. Metal expander with hard chrome plated surface is used for high speed application. Teflon sleeve is used for non-sticking application. Bow Rolls are also useful for removing of wrinkles, slack edges, spreading and slit separation.

Most of the Bow Expander Rolls are driven by web tension itself without any extra drive, used in Textile processing machines, Plastic converting machines, Paper Industries, processing, printing, laminating, coating, batching, winding and re-winding.

Bow angle adjusting worm-worm wheel gear box with hand wheel Metal is used for before high-speed Paper slitter re-winders for wrinkle removing and after slitting to separate slits. Big diameter Rolls having heavy weight and paper tension itself is not sufficient to drive the Roll. So extra pulley is provided to drive the metal bowed Roll.

Teflon Expander roll is particularly used before size press where wet working condition and extra drive is required to get the roll rotate. Teflon rubber bow roll is used for application where sticking of substance on the roll is a problem.

Double Axle Bow Roller

Double Axle Bow Roller / Jointed Axle Bow roller is widely used in Tyre Industry.

The unit consists of two numbers jointed axle bowed Rollers light duty or heavy duty as per application/fabric tension. Both sides of fabric edges are sensed by sensors and take correction as required by jointed axle bow rolls which works independently on both sides by the sensing given by each side sensor. These Double Axle bow rolls are available with hexagonal shaft 1-1/4� square bar for roll diameter 110mm or with 75mm shaft diameter and Roll diameter 160 mm for heavy duty applications.

We bring forth a range of Double axle bow roller that are designed for wrinkle removing of tire-cord fabrics. These rolls are manufactured using best quality raw material and as per international industrial standards. Our range is widely appreciated owing to their features of high strength, durability and resistance to chemical, abrasion and temperature. Further, we provide our range in different specifications and at most affordable prices.

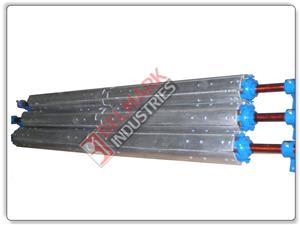

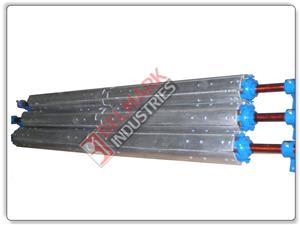

Slat Expander Rolls

Slat Expander Rolls – We manufacture Aluminum Slat Expanders that are used for wrinkle removing on coating machines which is available in any length and standard diameter 6″. Bigger diameter can be made in Extruded Aluminum Slat Expander as per specific requirements. Normally plain surface is provided but for some applications, serration is required on surface for gripping.

While ordering, one should provide the application temperature, web material, plain or serration required on surface, maximum speed of web material to meet all your requirements. For soundless working the rolls are also available with ball bearing type cam mechanism also. Normal expansion is 25 mm. We are one of the most reliable Aluminum Slat Roll Expander Exporters based in India.

Slat Expander Rolls are available also in wooden slat (Wooden Slat Expander Rolls) with felt covering and available in 6″ diameter , 8″ diameter & 12″ diameter in any working width. Slat Expander rolls are particularly suitable for slow speed machines like coating, cloth coating machines, Flat Bed Printing machine, artificial leather cloth before batching machine etc. The Roll is fitted with cam mechanism fitted with bearings with left & right slats from center. For longer width three slats are fitted and middle slats are fixed to avoid V shaped wrinkle-removing action. These are available with foot mounting pedestals.

Polyband Expander Rolls

POLYBAND EXPANDER ROLLS, ALUMINIUM POLYBAND EXPANDER ROLLS, POLYBAND EXPANDER FOR PP/LD/LDPE

Polyband Expander rolls are used for some web materials where other rollers like Bow Rubber expander roll, Slat Expander Rolls or Scroll rolls are not suitable for removing wrinkles. This Roll comes in diameter 140 mm and working web width is more than 1000mm. If the web tension is not sufficient to drive the roll, extra drive like sprocket or pulley can be provided as per requirements. Special elastic cord fitted on cam mechanism can be adjusted for more expanding action. It is very important to install the Roll in proper warp angle to get maximum results. Maximum working width of Poly Band Expander.

Air Expanding Shaft

AIR EXPANDING SHAFT

AIR EXPANDING SHAFT, CANTILEVER AIR SHAFT, LUG TYPE AIR SHAFT

Air Expanding Shaft is one of our widely sold and accepted product by our valued clients in the market, The design of Air Expanding shaft has been crafted keeping in mind all industry specific designs and sizes.

For fast change over of un-winder/winder roll air expanding shafts are required for core holding. Through its air valve air can fill and the air shaft will hold the core by expanding the rubber bladder. Core gets released after removing the Air by thump press. Most commonly used cores are 3 inch ID core but bigger cores are also used where heavy weight of the unwind/re-wind rolls. Air expanding shaft is core-holding device suitable for 3 inch core inside diameter & 70mm core diameter. Lugs type Air expanding shaft is most commonly used for paper or PVC core holding.

| Specifications | |

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.