Home

WELCOME TO BELLOSEALS VALVES

large volume and wide variety of hazardous and toxic materials are currently in use. Coupled with increasingly stringent regulatory requirements positive containment and control measures have become mandatory.

Bell-O-Seal Valves are well qualified to provide technological assistance for applications involving hazardous and difficult to- handle fluids and gases.

Bell-O-Seal engineers combine more than 20 years of experience in valve design and development with expertise in metallurgical techniques. Their strategic use of Special materials and other high performance metals makes Bellow Seal Valves the optimum choice worldwide for a broad range of applications.

The exceptional versatility, superior operating characteristics, robust construction and consistent dependability of Bell-O-Seal Valves have won us widespread acceptance across the industry, especially chemical and hydrocarbon processing industries.

Typical applications of our valves include : Thermic fluid, Ammonia, Chlorine, Phosgene, Butadine, Benzene, Ethylene, Hydrochloric acid, Hydrogen, Steam, Fatty acid to name just a fraction of the many possible uses.

Our uniquely engineered, of time and performance tested, Bellow Seal Valves assure safer operating conditions and compliance with anti-pollution regulations.

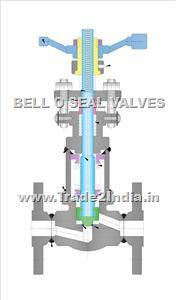

Our 'Zero Stem' leakage design eliminates product losses, hazards to humans, the environment, and costly downtime required for packing maintenance.

Our Valves are available in all popular sizes in flanged, threaded as well as weld end configurations.

Products & Services

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.