ARCOTECH LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ARCOTECH LTD.

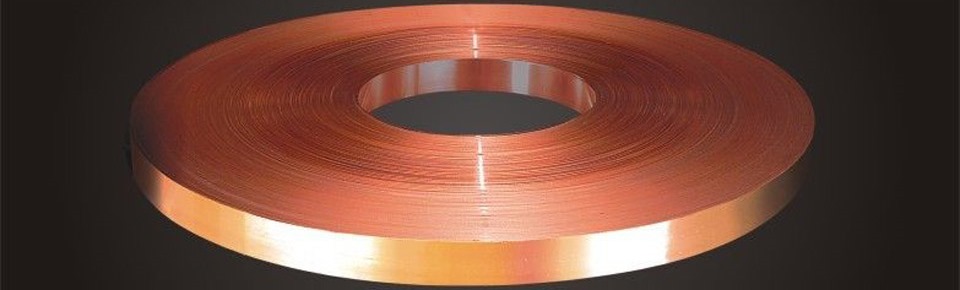

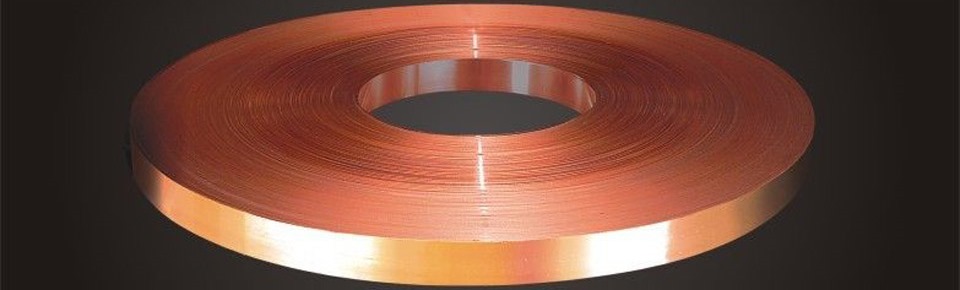

Foils

We produce high quality copper foils with minimum thickness of 35 µm in different grades that is manufactured from Grade I copper cathode. Following grades are available based on the requirements for various applications:

Electrolytic tough pitch copper(ETP Copper)

Deoxidized low residual phosphorous copper( DLP Copper)

Deoxidized high residual phosphorous copper(DHP Copper)

Tin bearing Copper(TBC)

General properties

Excellent electrical and thermal conductivity

Sustainable material, almost 100% recyclable

Extreme durability

Chemically pure

Good corrosion resistance

Good mechanical and metallurgical properties

Excellent dimensional accuracy

Excellent surface finish and oil free

Applications

Our range of dimensions, colors, and finishes combined with our extensive metallurgy background has consistently expanded our range of applications

Screening of XLPE cable

Electronic connectors

Transformers

Heat exchangers

Radiator fins in automobile

Solar panels

Gaskets

Tooling, embossing and fine craft

Strips

Copper Strips

High quality Copper strips in various dimensions and tempers are available that is produced from Grade I copper cathode. Depending on the suitability for the application they are available in following grades:

Electrolytic tough pitch copper (ETP )

Deoxidized low residual phosphorous copper (DLP )

Deoxidized high residual phosphorous copper (DHP )

Tin bearing copper(TBC)

Oxygen free high conductivity copper(OFHC )

General Properties

Excellent electrical and thermal conductivity

Sustainable material, almost 100% recyclable

Extreme durability

Chemically pure

Good corrosion resistance

Good mechanical and metallurgical properties

Excellent dimensional accuracy

Excellent surface finish and oil free

Applications

Our range of dimensions, colors, and finishes combined with our extensive metallurgy background has consistently expanded our range of applications

Electrical components

Electronic connectors

Telecom connectors

Transformer winding

Heat exchanger, boilers, pressure vessels

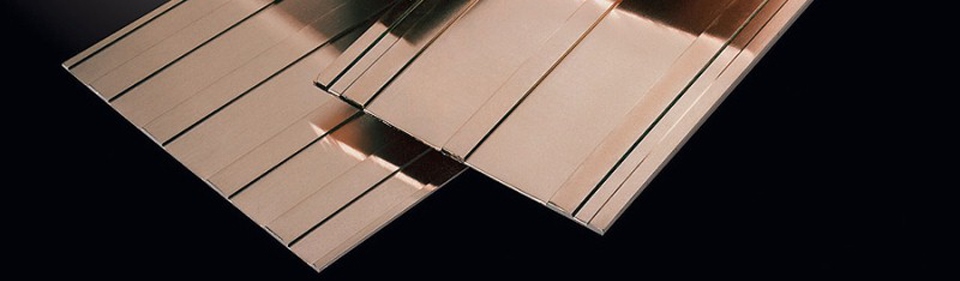

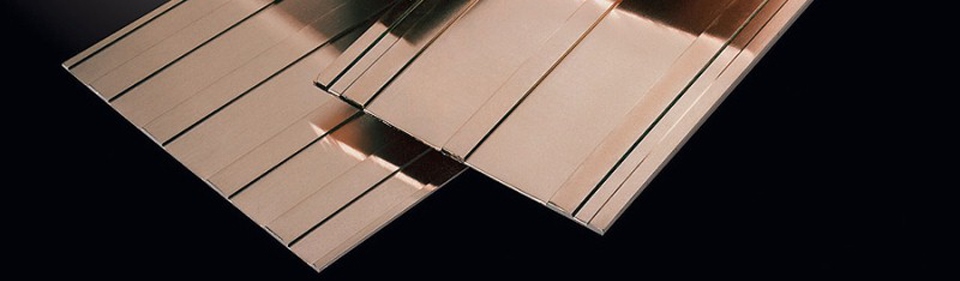

Sheets

Copper sheets

Copper sheets Description Copper sheets with different technical specifications are available to meet client requirements. We offer following grades of copper sheets which are produced from Grade I copper cathode:

Electrolytic tough pitch copper (ETP )

Deoxidized low residual phosphorous copper (DLP )

Deoxidized high residual phosphorous copper (DHP )

Tin bearing copper(TBC)

General Properties

Excellent electrical and thermal conductivity

Sustainable material, almost 100% recyclable

Extreme durability

Chemically pure

Good corrosion resistance

Good mechanical and metallurgical properties

Excellent dimensional accuracy

Excellent surface finish and oil free

Applications

Our range of dimensions, colors, and finishes combined with our extensive metallurgy background has consistently expanded our range of applications

Electrical components

Electronic connectors

Telecom connectors

Heat exchanger, boilers, pressure vessels

Gaskets

Plated

We offer plated copper and brass strips which are highly reliable materials. Copper and brass strips are plated to improve their solder-ability, electrical connectivity and corrosion resistivity. These are highly reliable materials. The press workability does not change after plating and these strips can be formed into complicated product shapes. Plating thickness is will be 0.5 to 2 µm or as per customer requirement.

General properties

Excellent corrosion resistance as compared to un plated strips

Excellent bonding of plated material with base material.

Better electrical connectivity

Better solder-ability

Good mechanical and metallurgical properties

Good dimensional tolerances.

Applications

Terminals/connectors

Electric and electronic parts

Multi Gauge

We produce multi gauge strips according to customer design. The material properties are homogeneous and dimensions are extremely precise.

The advantage of using multi gauge strip over single gauge strip is that the components which used to be assembled from one or more components, obtained from a multi gauge strip in single stamping operation thus eliminating the costly manufacturing operations after stamping.

General Properties:

Good electrical conductivity

Close tolerances on width and thickness

Uniform mechanical properties.

Cost effective at stamping as less stamping forces, higher stamping speed and less complicated and lighter die

Applications:

Power transistors

Connectors, switches and relays

Power LED

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.