ACE INSTRUMENTS AND SERVICES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ACE INSTRUMENTS AND SERVICES P.LTD.

Cloud And Pour Point

Combining a revolutionary patented built-in cooling system and highly precise detection mechanism, ISLs CPP 5Gs performs pour and cloud point testing of any petroleum products, down to -95C (-139F), in accordance with all the international standards. Its unique cooling technology eliminates external liquid connections, heat, and noise, but also the maintenance associated with external cooling. Automation enables unattended operation with excellent reproducibility and repeatability. It is ready to work whenever and wherever you are; simply plug in the electrical cord, and begin testing. Pour point is detected by tilting the sample no turning, pressing or twisting as an optical surface, whereas detection system precisely monitors movement of the specimen surface. Optics detect cloud point in the specimen when wax crystals first appear.

Cold Filter Plugging Point

Ultra low temperature cold behavior testing -- powerful, portable. The FPP 5Gs is the first portable automated Cold Filter Plugging Point (CFPP) instrument that strictly conforms with IP, EN and JIS test methods. Fully self-contained with its own built-in cooling system, this instrument achieves cooling temperatures down to 69C without any external liquid connection. The FPP 5Gs is 100% user configurable -- vacuum profiles, cooling profiles, suction intervals, cleaning phase as well as many other parameters may be modified on this stand alone instrument. Advanced optics detect sample flow, eliminating the direct pipette contact required with manual testing.

Freeze Point

ISLs FZP 5G2s provides highly accurate freezing point determinations down to -100C (-148F), helping you assure the low-temperature flow performance of your aviation fuel. It combines a patented built-in cooling system and a unique, patented detection cell into an ultra-compact, easy to use instrument that is ready to work whenever and wherever you are. Simply inject approximately 10 ml of sample and press Test; no pre-test programming is necessary. The unit automatically controls test progress and deliver precise results in less than 15 minutes. Self-cleaning operation speeds and simplifies testing, while smart software features assure accurate testing of difficult and contaminated samples.

Mini Cloud And Pour Point Automatic No Flow Point Analyzer

Designed to provide highly accurate cloud and pour point temperatures of petroleum products during cooling, ISLs automated Mini Cloud Pour Point Analyzer is compact, portable and delivers fast results (30C in less than 30 minutes, and quick pour point correlation with no flow @ 0.1C determination). Easy single button operation involves placing a tube filled with test specimen on the sample changer and pressing the OK key. MPP 5Gs powerful built-in cooling system with selectable cooling profiles requires no special programming or prior cloud and pour point measuring test knowledge. The MPP 5Gs automation will significantly increase test productivity and improve repeatability and reproducibility.

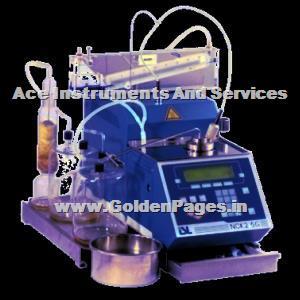

Automated Noack Apparatusnoack

ISLs safe, easy to use NCK2 5G Noack evaporation loss analyzer enables the most precise testing to meet increasing QS/QA requirements in full compliance with CEC, ASTM & IP methods. The Noack Volatility Test is used to determine evaporation loss of lubricating oils, an issue of particular importance in engine lubrication. Designed for routine day-to-day work in labs with high sample workloads, the NCK2 5G test initiates with a few simple keystrokes. Smart assistance features automatically alert the operator if any test device is not properly set, and the instrument carefully tracks sample temperature and vacuum throughout the tests duration, providing a digital display of each and recording the values to memory. NCK2 5Gs advanced quality control features including traceable automatic calibrations with lock-out control and detailed test reports with tracking numbers of all measuring devices fulfill strict ISO 9000 quality system requirements. The metal temperature probe is delivered with an engraved serial number and traceable calibration certificate. Extended local memory capacity, graphic printer connection and PC link enable powerful, flexible results management.

Laboratory Micro Distillation

ISL PMD 110 is a state-of-the art solution for fast and reliable response distillation analysis. It is in accordance to ASTM D7345 and in perfect correlation with ASTM D86 (groups 0-4), D1160, ISO 3405 and IP 123. Based on an innovative micro-distillation method, the PMD 110 determines the boiling range characteristics of any commercially available petroleum product, including light and middle distillates (process streams, in less than 10 minutes and using only 10ml of sample. Being compact, robust and portable design, the PMD110 is easily installed in labs or ideal for on-site locations, for refining, for refining process control, fuel blending, research or mobile applications (fuel adulteration monitoring and fast quality screening).

V.I.D.A Density Meter

The ISL VIDATMdensity meter offers unmatched reliability in density measurement through a very user-friendly, fully automated, one button-push operation. The VIDATMis based on the proven oscillating U-tube method and integrates innovative features that ensure reliable and accurate analysis of crude oil & petroleum products from volatile to the highly viscous ones in compliance with ASTM D4052, ASTM D5002, ASTM D5931, ISO 23296 (IP365), ISO 15212, DIN 51757, JIS K2249. Its high level of automation powered by embedded smart software allows non-assisted operation during the whole test cycle, therefore a significant reduction of operators workload, together with repeatable and consistent measurements one can rely on.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.