TELELIN INSTRUMENTS INDIA

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TELELIN INSTRUMENTS INDIA

Vacuum Gauge Dead Weight Tester

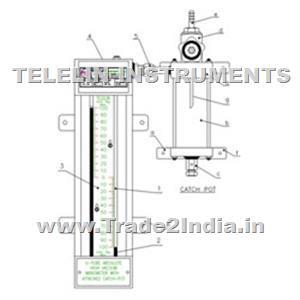

Model No. GT-55 For calibration of vacuum gauges and other sensing, transmitting and recording vacuum instruments. The Vacuum Gauge Tester is a quick and convenient method of calibration free from the disadvantages of using the fragile mercury Manometer. The main components of the tester are :

SCREW PUMP to generate the vacuum in the tester conveniently and precisely of adequate capacity and operated by turning the spooked handle.

FREE PISTON Assembly of special steel, hardened, tempered, ground and lapped to accurate size and very fine surface finish to provide true floating action. The free piston is suspended vertically downwards from a rigid frame and connected by a pipe to the screw pump. A CARRIER weight is attached to the free piston for taking more weights.

A VALVE is provided to connect the circuit to the atmosphere and thus check zero of the gauge.

GAUGE CONNECTOR of ½" BSP (F) union for connecting gauge to be tested. Other sizes of gauges can be connected by using adapters.

SET OF WEIGHTS directly marked in convenient values of vacuum and easily stacked on the CARRIER weight. Available in either/and kgf/cm², mmHg, inHg units. Storage box is provided.

BASEPLATE of sturdy construction having legs and leveling screws will be also provided.

STANDARD RANGES

|

Minimum Vacuum

|

Smallest Step

|

Maximum Vacuum

|

Unit

|

|

0.1

|

0.02

|

0.96

|

kgf/cm²

|

|

50

|

10

|

710

|

mmHg

|

|

2

|

0.5

|

28

|

inHg

|

Please specify the unit of calibration required. If this is not specified, the weights will be supplied in mmHg unit. Extra sets of weights in other units with same tester can be supplied on extra cost but must be ordered at same time.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.