TECHNO CONTROLS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECHNO CONTROLS

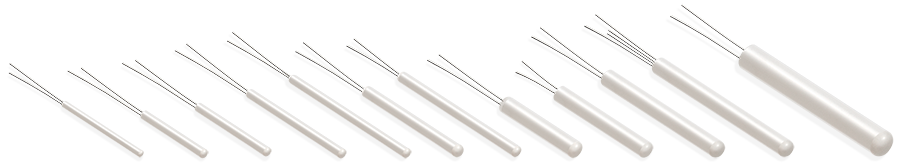

Wire Wound Rtd

General description for RTD elements

Temperature is one of the important basic or fundamental quantity of a matter and it defines the thermal energy of the matter. It is measured in various units like °C, °F, and °K. All these units are quite well defined by International Temperature scale ITS 90. Among various methods of temperature measurements, thermocouples, resistance thermometers and thermistors are most popular. The reason being they provide electrical signals, which can be connected to, sophisticated indicating, controlling and recording instruments. Over the range of –200 deg c to +962 deg C, accepted standards is the Standard PRT i.e. Platinum Resistance Thermometers. The basic principle of resistance thermometry is that the resistively of metal depends upon it’s temperature. It is an absolute method of measurement (As compared to thermocouple which measures temperature difference) For a particular metal, a curve can be obtained for resistance versus temperature. The base metal used in resistance thermometry are Platinum, Copper and Nickel. Since early days, resistance thermometry has gone to considerable changes and they are now extensively used in industries. At temperature below 650 deg C, the industrial resistance thermometer are now more accurate and reliable than any other sensors. The increase in use of microcontroller based linearised instruments increases the choice of RTDs .

Among all the base metals, Platinum is now a days the best choice in the industries. Platinum being a noble metal retains its characteristics for longer time. For wide temperature range Platinum Resistance thermometer follows the equation as defined below,

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Stator Winding Rtds 62147.jpg)

Stator Winding Rtds 62148.jpg)