SWIFT AUXI TECHNIK P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SWIFT AUXI TECHNIK P.LTD.

Water Chiller (Air Cooled)

55507.jpg)

Unique Features

Microprocessor / PLC based control

Energy efficient & reliable scroll compressor with hermetically sealed suction gas cooled motor

High performance, low maintenance system with switching cycle control

Crank case heater to prevent liquid migration of refrigerant in compressor

Filter dryer to ensure moisture free system

Sight glass with moisture indicator

Large size stainless steel insulated tank to prevent heat loss

Dry running protection of pump by water level sensor in the tank

Water re-feeding valve to maintain level in the tank automatically

Antifreeze thermostat for protection of evaporator and compressor

High volume, high pressure pump with stainless steel impeller

Inbuilt process water bypass with valve

All chilled water contact surfaces are non ferrous for protection against corrosion

All wetted surfaces are stainless steel, copper or other non ferrous material

Proven component suppliers like Danfoss, Copeland, Grundfos, Ebm, Siemens have been chossen for ultimate reliability

Tool free access panels and a neatly organized internal component layout provide easy access and service. Simply remove the panels to gain access to the entire cabinet of the chiller

Water Chiller (Water Cooled)

55508.jpg)

Unique feature

Microprocessor / PLC based control

Energy efficient & reliable scroll compressor with hermetically sealed suction gas cooled motor

High performance, low maintenance system with switching cycle control

Crank case heater to prevent liquid migration of refrigerant in compressor

Filter dryer to ensure moisture free system

Sight glass with moisture indicator

Large size stainless steel insulated tank to prevent heat loss

Dry running protection of pump by water level sensor in the tank

Water re-feeding valve to maintain level in the tank automatically

Antifreeze thermostat for protection of evaporator and compressor

High volume, high pressure pump with stainless steel impeller

Inbuilt process water bypass with valve

All chilled water contact surfaces are non ferrous for protection against corrosion

All wetted surfaces are stainless steel, copper or other non ferrous material

Proven component suppliers like Danfoss, Copeland, Grundfos, Siemens have been chossen for ultimate reliability

Tool free access panels and a neatly organized internal component layout provide easy access and service. Simply remove the panels to gain access to the entire cabinet of the chiller

All chillers are factory tested under load prior to shipment

Shell and Tube Condenser - high surface area with externally finned copper tube, design for Indian ambient condition

Brazed Plate Evaporator / Shell and Tube Evaporator - provide higher heat transfer coefficients due to reduced fouling

Evaporator Stainer - protects the evaporator from solid contaminants in the process water stream

Condenser Water Strainer - helps to protect the condenser from solid contaminants in the condenser water

Air Chiller (Air Cooled)

55509.jpg)

Advantage

Air Chiller Air Cooled is used to supply a cooled air ring of blown film extrusion line. Cooling of air with the help of direct expansion of refrigerant saves energy compare to conventional water chiller plus heat exchanger system

Air Chiller Air Cooled is used to supply a cooled air ring of blown film extrusion line. Cooling of air with the help of direct expansion of refrigerant saves energy compare to conventional water chiller plus heat exchanger system

Five SAC series chillers have cooling capacity of 9.4 TR to 28.5 TR with operating temperature of 5°C to 20°C in ambient air temperature up to 40°C

Compact in size which reduce foot print up to 25% compare to conventional water chiller plus heat exchanger system

Air Chiller Water Cooled

Advantage

Air Chiller Air Cooled is used to supply a cooled air ring of blown film extrusion line. Cooling of air with the help of direct expansion of refrigerant saves energy compare to conventional water chiller plus heat exchanger system

Air Chiller Air Cooled provides consistent air temperature irrespective of ambient condition which is very essential for processing of plastics on blown film lines

Five SAC series chillers have cooling capacity of 9.4 TR to 28.5 TR with operating temperature of 5°C to 20°C in ambient air temperature up to 40°C

Compact in size which reduce foot print up to 25% compare to conventional water chiller plus heat exchanger system

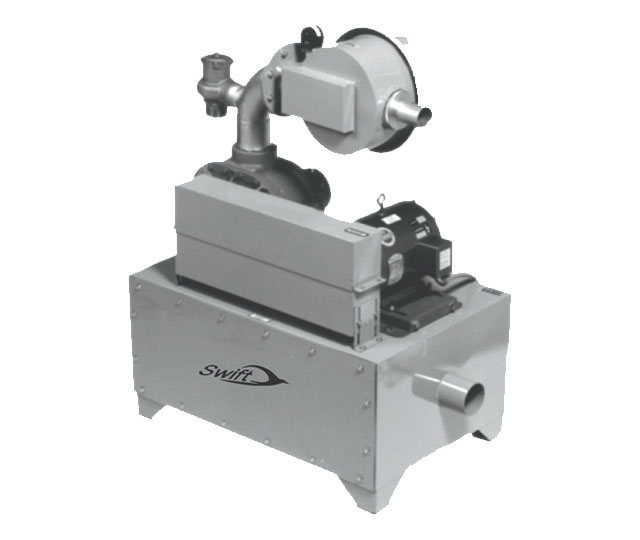

Screw Chiller (Air Cooled Water Chiller)

55511.jpg)

Screw Chiller (Air Cooled Water Chiller)

Cooling Capacity from 30 TR to 100 TR Energy Efficient Central Chilling Plant.

Provide chilled fluid for industrial application from a central location with the Swift Air Cooled SK series central chillers.

Simple design of screw compressors provide both full load and part load efficiencies unmatched in the industry, and result in lower energy costs when compared to reciprocating compressors.

Mould Temperature Control

Unique Features

Precise control of temperature by PID temperature controller

Oil based system for maximum 150°C temperature

Water based system for maximum 95°C temperature.

Digital display of set and actual value on screen

Air purging facility for mould changes

High flow and high pressure powerful pump.

Easy to operate.

Dry running protection of pump by level monitoring device.

Automatic water refilling provision in water based unit.

Painted with P.U. paint

Accessibility from all sides

Corrosion proof material in water line.

User friendly control and fault indication.

Overload protection of pump.

Audible alarm for fault indication.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

55501.jpg)