SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Dust Separators

SDS is suitable for removing dust in plastic materials such as PET, PA, and PC etc. It is not used for dealing with plastic recycled materials. Please inform us as the material need anomalous temperature or close-loop circulation after drying. SDS-100/250 is only applicable for the dust-separating of virgin material; SDS-500 is applicable on the floor mount.

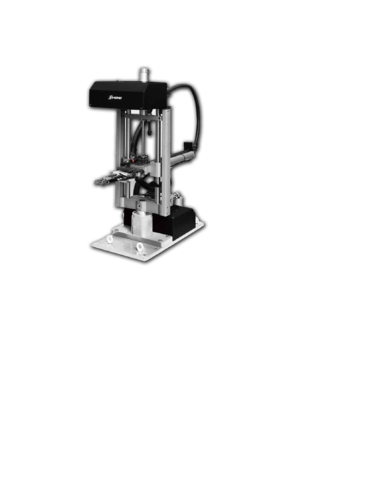

Screenless Grinders

SG-14 series granulators operate in super low speed to cut materials into well-proportioned granules. There are least dusts produced in the cutting process. Multiple security devices ensure high safety grade; automatic reverse running function ensures continuous operation. This series of screenless granulators are suitable for granulating hard and thick materials. For SG-24T series, there are two gear motors and two cutting chambers to work simultaneously. It can granulate the sprues and waste material, also is capable of granulating long and thin or tough sprues.

Low Speed Granulators

SG-16N/20N series low-speed granulators are suitable for crushing sprues material and a few rejects. It is set on the side of Plastics Molding Machines and Picker, collocating with belt conveyor. It features low speed, big driving torque, low noise, little dust level and simple operation.

Plastic Grinder

SG-23E/30E series of "Standard" central granulators are built to conform to sound-proof models both in safety configuration and operation security. They are suitable for centralized recycling of wastes and rejected products from injection, blow moulding and extrusion lines. The granulators feature optimal structure, easy operation and quick blades changing. Staggered rotating blades can easily grab and cut through the materials and ensures low energy consumption.

Screenless Standard Granulators

SG-24E series "Standard" screenless granulators are suitable for instant recycling or granulating hard and thick materials. With European-type appearance and compact size, they feature low rotating speed, low abrasion and super soundproof. Unique cutting blades design ensures well-proportioned granules and minimal amount of dusts. Easy for material cleaning and safe to operate. The unique transmission design cuts the cost greatly.

Screenless Granulators

SG-24N series granulators operate in super low speed to cut materials into well-proportioned granules. There are least dusts produced in the cutting process. Multiple security devices ensure high safety grade; automatic reverse running function ensures continuous operation. This series of screenless granulators are suitable for granulating hard and thick materials.

Screenless Granulator

SG-24T series granulators operate in super low speed to cut materials into well-proportioned granules. There are least dusts produced in the cutting process. Multiple security devices ensure high safety grade; automatic reverse running function ensures continuous operation. This series of screenless granulators are suitable for granulating hard and thick materials. For SG-24T series, there are two gear motors and two cutting chambers to work simultaneously. It can granulate the sprues and waste material, also is capable of granulating long and thin or tough sprues.

Sound Proof Central Grinders

SG-36 series sound-proof central granulators are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding or extrusion lines. The machines feature optimized structure, easy operation, and quick blade replacement. Staggered rotating blades can easily grab and cut through materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum.This granulator has various models with wide application range to meet different customer’s demand.

Sound Proof Central Granulators

Introduction SG-23/30/36 series sound-proof central granulators are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding or extrusion lines. The machines feature optimized structure, easy operation, and quick blade replacement. Staggered rotating blades can easily grab and cut through materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum.This granulator has various models with wide application range to meet different customer’s demand. SG-50 series granulators are applicable to granulate various kinds of plastic materials from injection moulding, blow moulding or extrusion moulding. This series feature compact design, easy operation and quick blade replacement. It is great in motor power, cutting chamber size, and output capacity. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level.

Sound Proof Central Granulator

Introduction SG-43 series are suitable for centralized recycling of waste and rejected parts form injection, blowing molding and extrusion lines. This series feature compact design, easy operation and quick blade replacement. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level ensures low energy consumption.

Plastic Film Granulator

Introduction SGF-29 series are applicable for granulating and recycling plastic films. After pressed toughly by the material feeding rollers, films are pushed and cut into granules for reusing. They feature easy operation, excellent quality, reasonable price and compact in size. Infinitely adjustable rotating speed reduces the dust, noise and abrasion of knives. Various kinds of safety devices meet the requirement of CE.

Sound Proof Grinders

Introduction SG-70 series granulators are applicable to granulate various kinds of plastic materials from injection moulding, blow moulding or extrusion moulding. This series feature compact design, easy operation and quick blade replacement. It is great in motor power, cutting chamber size, and output capacity. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level.

Sounds Proof Central Granulator

Introduction SG-23/30 series sound - proof central granulators are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding or extrusion lines. The machines feature optimized structure, easy operation, and quick blade replacement. Staggered rotating blades can easily grab and cut through materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum.This granulator has various models with wide application range to meet different customer’s demand.

Screenless Granulato

We are also engaged in manufacturing and supplying high quality Screenless Granulators, which operate in super low speed to cut materials into well-proportioned granules. Fabricated utilizing high-tech machines and advanced techniques, the range is appreciated for producing least dust in the cutting process. Further, to ensure high safety grades the range is designed with multiple security devices and for continuous operation the automatic reverse running function is used. Suitable for granulating hard and thick materials, our SG-24T series of screenless granulators comes with two gear motors and two cutting chambers to work simultaneously. In addition to granulating the sprues and waste material, these also have an effect on long and thin or tougher sprues materials.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

51164.jpg)

51166.jpg)