SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Hopper Dryer

Our clients can avail from us Standard Hopper Dryers or SHD series, which is acknowledged for offering an effective and low-cost method for plastic material drying. Manufactured with utmost precision, the range uses hot air to dry materials that become wet due to moisture absorption during packaging, transportation and recycling cycles. Easy to install, these dryers can be mounted on the moulding machines for both the benefits i.e. quick drying and space saving. High performing, the series is designed in such a way that allows the hot air to blow evenly from top to the bottom (both SHD-800 and SHD-1000 have down-blowing air pipe and accessible door for easy material clearance) of the hopper with capacity ranging from 12~1,000kg. Moreover, our models are offered with 24-hour timer as per the requirement of the clients.

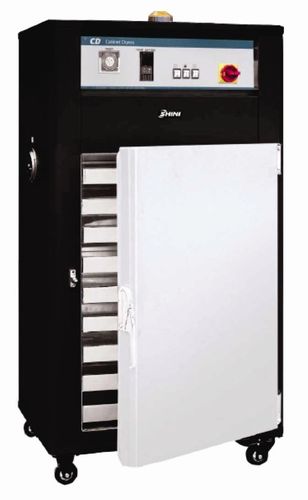

Cabinet Dryers

CD series of cabinet dryers are mostly used for simultaneous drying of different kinds of polymers in small quantities or for drying materials for trial moulding. They can also be applied in electronic engineering, electroplating, pharmacy, paint baking, printing industries, etc. for preheating or drying related products.

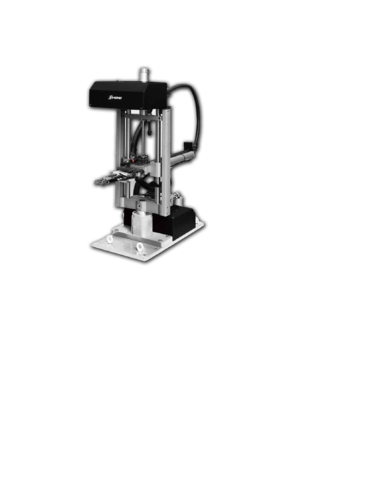

Compact Dryer Dehumidifier And Loader

SCD series dehumidifying dryer gathers dehumidification, drying and two-stage conveying three functions, is very suitable for drying engineering plastics materials with hygroscopicity such as PA, PC, PBT, PET. Of them is Optics SCD could be used in processing application of lens, LCD backlight board and discs, it has dew-point of below -40under ideal condition.

Pet Crystallizers

SCR closed-loop crystallize-rs are used for constant crystallization of un-crystallized PET regrinds or pellets. Processed materials can then be dried and dehumidified directly. This system mainly consists of heating elements, insulated hopper and agitator screw mixing device. After un-crystallized PET materials fed into the hopper, the system starts crystallization and agitator starts blending to prevent formation in lumps. Crystallized materials can be conveyed to material storage bin or into drying hopper.

Dehumidifier Dryer

SDD series dehumidifying dryers combine dehumidifying and drying systems into a single unit. They have many applications in processing plastic materials, such as PA, PC, PBT, PET etc. All models feature SD-H honeycomb dehumidifiers with built-in process heater and insulated drying hopper. Under ideal conditions, it can provide dehumidified dry air with a dew-point lower than -40

Drying Loaders

SDL-U series of drying loaders combine conventional hot air drying and two-stage conveying functions into a compact unit. It is particularly suitable for using with the big tonnage moulding machines when height restriction is concerned at the workshop. The SDL-U series has a unique function of two-stage conveying that can transport both raw material to its own drying hopper and dried material to the moulding machine.

Heatless Dehumidifying Dryers

SDL-U series of drying loaders combine conventional hot air drying and two-stage conveying functions into a compact unit. It is particularly suitable for using with the big tonnage moulding machines when height restriction is concerned at the workshop. The SDL-U series has a unique function of two-stage conveying that can transport both raw material to its own drying hopper and dried material to the moulding machine.

Hopper Dryers Euro Model

SHD-U series hopper dryers adopt hot air down-blowing design and use stainless steel made material hoppers to avoid contamination. With this design, they are also ideally suitable for use with honeycomb dehumidifiers to dry engineering plastics. There are 25 models available, ranging from 20 to 8,000 liters.

Plastic Dehumidifying Dryer

The Heatless Dehumidifying Hot-air Dryer is made of stainless steel and equipped with athermal regeneration type of air dryer, which is able to dry plastic raw materials with stable and low dew-point dry air without heating and regeneration. Features dry air down-flouring and cyclone exhaust and double insulated lager design, suitable for dring hygroscopic engineering plastics which are hard for common hopper dryer. Besides, it is also featured by its low power consumption and short drying time. This series is able to provide machines with three feeding capacities of 40L, 80L and 120L.

Mould Dehumidifier

SMD series mould sweat dehumidifiers are designed to remove the moisture sweat from condensing on the mould surface. Forming of moisture sweat on the mould surface is due to the use of chilled water for reducing the moulding cycle time, particularly while moulding of the PET preforms. To bring about the moisture sweat on the mould surface is because the mould surface temperature is lower than the dew-point temperature of surrounding air, thus the water vapor comes into being, then causes corrosion of mould and effects quality of moulding parts as well as production efficiencies. This series of machine uses honeycomb rotor to carry out dehumidifying function, which generates a dry airflow with dew-point ranging from +5~-10, and ensures the surrounding air of mould remaining in a low dew-point temperature. It provides constant low dewpoint surrounding air to the mould surface all year round without being influenced by the change of seasons.

Dehumidifier

SD-H series honeycomb dehumidifiers are mainly used to dry hygroscopic engineering plastics. A honeycomb-rotor is used to offer effective drying, which under ideal conditions, can supply dehumidified dry air with a dew-point lower than -40.This series comprises 14 models of honeycomb dehumidifiers, the largest of which can provide dry air up to a quantity of 4,000 m3/hr.

Dryer Loaders

Introduction SDL series “Standard” Drying loaders integrate plastic drying and loading into one unit. Especially applicable to those large injection moulding machine which are placed in height limited workshop. This combination offers a group of standard photosensor hoppers, which can be used to load dried materials. Besides, SAL-900G is available for choose to realize the two-stage loading function.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

51164.jpg)

51166.jpg)