RSB TRANSMISSIONS I LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to RSB TRANSMISSIONS I LTD.

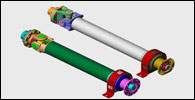

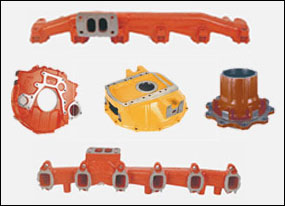

Transmission Components

RSB's Gear Transmission units provide in-depth product support to prospective OEM clients based on its vast industry experience and expertise. It manufactures an extensive range of fully finished gears at two of its plants that are strategically located to cater to diversified industry sectors inclusive of Commercial Vehicles, Passenger Cars, Tractors, Pump OEM's. RSB is renowned for its customer services such as, fast turn around and individual attention to complex orders.

Manufacturing

The plants have organized amenities for Gear Cutting, Heat Treatment, Finishing and Final testing under one roof, complying with DIN Class 7/9. Advanced CNC Gear Cutting Machines for Hobbing, Shaving, Shaping and Sealed Quench Furnace for Carburising & Carbo-Nitriding have been installed.

The equipments also include a complete package of Metallurgy & Metrology comprising CNC Hoffeler Gear Tester, Carl Zeiss Microscope & Zwick Micro Hardness Tester.RSB identifies the requirements of the customers and accordingly establishes Manufacturing Cells to ensure consistent quality with on-time deliveries.

Product Range & Specifications

Spur & Helical Gears

30 to 310mm dia, Module 1 - 8

Geared Shafts

600 mm length

Sleeves Plain

up to 250 mm dia

Sleeves Broached

up to 120 mm dia

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.