LITHOTECH ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to LITHOTECH ENGINEERS

Hammer Mill

The most versatile machine that is used to grind almost all materials like spices, foofstuffs, chemicals, ayurvedic herbals, minerals and other miscellaneous materials.

The grinding takes place between the high speed swinging hammers and top/side liners. Once the particle size reduces to that of the perforated screen at the bottom, it will discharged through the hopper.

The fineness of the material can be controlled by changing the spend of the rotor(hammer), content of serrations on liners number of hammers and diameter of perforation on the screen.

[Hammer Mill]

MODEL

Food Chopper

Chopper has been specially designed for granulating & cutting various materials like foodstuffs, agro,ayurvedic herbs, etc. into small pieces of required size with minimum of powder content. There is no heat generation while grinding thereby retaining important properties like aroma taste flavour and colour.

Some typical applictions are making crushed chillies for pizza toppings,chopped / minced / granulated onions, tea-cut herbal products, granulating of food colours, gum, asafoetida, crushing of various ayurvedic herbs for Extraction purpose, etc.

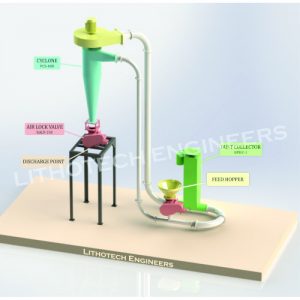

Micro Pulverizer

It is utilized for soft materials like chemicals, dyestuffs, foodstuff, pharmaceutical, bulk drugs, etc. for fine grinding. Since the machine is used vastly for chemicals & bulk drugsand other heat sensitive materials, it has a built in water jacket to control the temperature in the grinding chamber.

The grinding takes place through atirition between the high speed swinging hammers and the serrated liners. Due to the very high speed and a small chamber, a higher fineness is achieved as compared to hammer mill.

Pin Mill

This machine is used for very soft materials like sugar, salts, chemicals, dyestuffs, etc for medium fine to fine grinding. This material is centrally fed into the machine chamber. The grinding takes place between a high speed rotor consisting of a large number of pins and a stationary stator. The discharge takes place through the perforated screen throughout the periphery.

Ultra Fine Mill

This is screenless pulveriser used for grinding soft to medium hard materials into super fine powder. The machine have built-in water jacket to keep down the tempature in machine chamber. This machine is generally used for superfine grinding of food dyes, industrial dye intermediated, pharmaceuticals drugs, chemicals, etc. The feed is through the feeder screw that feeds material into machine chamber.

The grinding takesplace duo to attrition between a high speed rotating rotor having six wear resitant tips and side linears on both side of the tips and also a turbo effect. The annular gap plate controls the floe of materials through the mill. In other words it regulated the fineness of the material. The powder is discharged through the bottom hopper.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.