FYKAYS ENGINEERING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FYKAYS ENGINEERING P.LTD.

Flue Gas Analyzer And Controller

SCALE LOSSES AND FUEL LOSSES are the biggest causes of concern for all re-heating furnace owners, particularly in these recession–hit times.

Scaling Loss:

On an average, Indian scale loss is 1.5% to 3.5%. However, not many people are aware that the average International scale loss is 0.2% to 0.8%. It is possible to limit scale losses and match international standards. A rough estimate is that a scale loss of 1% in a daily production of 100 MT of rolled steel will cause a loss of Rs.36000/- per day i.e. Rs.108 lacs per annum.

Fuel Loss:

Indian consumption of fuel per MT of steel rolled is anywhere between 38 to 55 litres, which is, again, way above the International average consumption of Furnace oil 25 litres/MT.

A reduction in fuel consumption by even 10% would effect savings of upto Rs. 11700/- per day or approximately Rs. 35 LACS per year (at an average consumption of 45 litres / MT and at a production level of 100 MT per day and taking the cost of Furnace Oil to be approximately Rs. 26/ Litre).

Scale losses and increased fuel consumption are caused mainly due to too much excess air in the furnace due to incorrect air: fuel ratio, causing the excess oxygen to oxidize the job in the re-heating furnace and sensible heat being carried away from the furnace requiring more fuel to be pumped in.

Re-heating plants across India are thus losing lacs and lacs of Rupees every year. What is the solution.

1. "OXYCOMP-G" - FYKAYS ONLINE OXYGEN ANALYSER

The OXYCOMP - G works on the well–proven Zirconia sensor principle which enables detection of Oxygen in the furnace from PPM level to 100%.

The OXYCOMP-G has been specifically developed to monitor the amount of excess oxygen in the re-heating furnace gases. Once this is known, the user can control the amount of fuel injected.

For example, if the Oxygen percentage is too high (say 5%), the instrument will give an indication on the remote display and the air injected into the furnace will have to be reduced by the user. This will obviously reduce fuel consumption as well as scaling losses.

This document is the property of Fykays Engineering Pvt Ltd and may not be reproduced in any form without prior permission.

The basic components of Fykays OXYCOMP-G system are as follows:

Oxygen Probe: The Zirconia Oxygen probe which senses the Oxygen in the furnace atmosphere

Probe heating Furnace + Controller: A small auxiliary furnace which is installed on the side wall of the re-heating furnace in which the Oxygen probe is installed. This furnace temperature is controlled with the help of a PID controller.

The Oxygen Analyzer

The reference air system

The electronic purging apparatus

The remote display: The signaling panel with Hi/Lo alarm

Once the Oxygen content in the furnace atmosphere is indicated by the instrument, the fuel can be controlled manually. If desired, the output from this system can be used to automate the control of fuel injection into the furnace with the use of control valves.

2. OXYCOMP G-II FYKAYS OXYGEN ANALYZER AND CONTROLLER

Recognizing the industry requirement for automated control, we developed the OXYCOMP G-II. Essentially, it is also built around the well proven Zirconia technique and enables precise detection and control of Oxygen over a wide range.

In addition, this version of OXYCOMP G-II utilizes an equally well proven technology namely Variable Frequency Drive (VFD) to regulate the speed of the main air blower so as to reduce the air intake into the furnace so as to contain the excess free Oxygen, instead of having to depend on the furnace fireman.

Zirconia Oxygen Probe

FYKAYS offer two distinct types of IN-SITU PROBE

Reaction Bonded: (RB) unsheathed probes

Fusion bonded: (FB) sheathed probes

Reaction bonded probes, which can be used without external sheathing and the associated assembly and maintenance problems make use of a patented process in which a ZrO2 thimble or pellet is bounded onto an Al2O3 tube by reaction through a platinum washer.Fusion bonded sensors on the other hand use sintered ZrO2 pellet cemented and fused to the Alumina tube

Wider applications :

Length of Probes

Standard lengths available are 150, 300, 600, 900, 100, 1200 and 1500 mm. Longer lengths up to 2500 mm available on special request.

Thermocouple Specifications:

For RB sensors the thermocouples are normally type 'R' or 'S' (Pt.Pt.Rh 13 % or Pt.Pt.Rh 10 %)For FB sensors the choice is extended to 'K' type (chromel-alumel), for lower temperature applications.

For extra temperatures probes are supplied with 'B' type (PtRh 6% - Pt 30 %) thermocouples (RB sensors only) thermocouples (RB sensors only)

Specifications :

Temperature Limits

FB sensors upto 1400C

RB sensors upto 1800C

Applications :

Energy Conservation

Boilers of any / all types

Rotary Kilns

Reheating / heating furnaces

Forging furnaces

Forging furnaces

Tunnel Kilns

Heat Treatment furnaces

End use: Power plants, Cement, Sugar, Paper, Textile, Steel, Chemicals, Petro-chemical, Fertilizers, Ceramic and other industries

Furnace Temperature Measurement And Control

Temperature monitoring and control by sensing soaking zone temperature and regulating the air and fuel control valves by means of a PID controller, which can be either pneumatically or electrically actuated. The air : fuel ratio is built into the controller software. One of the noteworthy features of the temperature loop is the special facility provided for manual intervention – on occurrence of a mill breakdown, the furnace temperature can be turned down to pre-determined levels simply at the click of a button.

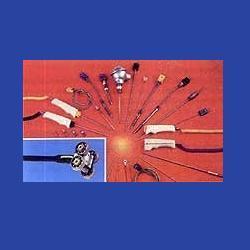

Process Control Thermocouple And Accessories

FYKAYS offers a very wide choice of thermocouples and accessories for industrial application. Carefully chosen components including premium grade thermocouple wires and other quality raw materials and special "made to specs" designs, ensure close accuracies, fast response, long deterioration-free service and other such high 'benefits to cost' advantages to users.

Types:

1) Sheathed

2) Bare

3) Button type

4) Bow type

5) Needle type

6) Roller type

7) Flexible bow type

Choice of Thermocouple:

1) Copper-Constantan

2) Iron-Constantan

3) Chromel-Alumel

4) Platinum-Platinum Rhodium 10%

5) Platinum-Platinum Rhodium 13%

6) Platinum Rhodium 6%

7) Platinum Rhodium 30%

8) Tungsten- Tungsten Rhenium 26%

9) Tungsten 5% - Tungsten 26%

Choice of sheath material

NON-METALLIC

1) Mullite

2) Silliminite

3) Recryst. Alumina Fused Silica

4) Berylia

5) Graphite, etc.

6) Fused Silica

METALLIC

Carbon Metal : SS 304, SS 316, SS410

Hastelloy, A,B, C or X, Monel, Tantalum, Iniconel, Incalloy Mollybdenum, etc.

Choice of construction

Simplex / Duplex, Straight, Right angle, 45 degree angle, Adjustable flange

Hot Junction: Exposed Junction, Covered Grounded or Ungrounded Junction

Calibration

Unless specified all our thermocouples are as per IPTS-68. Other calibrations can be made on request.

Accuracy

Normal : +/- 3/8 % of the read value

Special : +/- 1 C in specified range of operation

Certification : Special certification at specific reference points can be provided at extra cost.

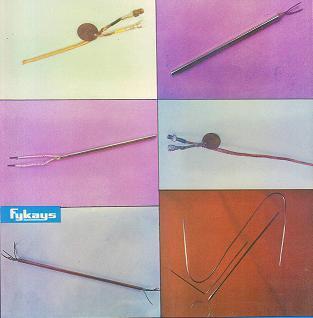

Mineral Insulated Thermocouple And Accessory

It is the Micouple Bow to the Industry's demand/Desire for Quality, Economy and Safety. Mi Couple is supple, Durable and Accurate to the Core. It is designed to be a part of the heating structure. In that process it stands BEATINGS in the beds and TWISTINDS in the walls so that it can keep in touch with the superhot materials and transmit the process temperatures Days in and Years out. Mi Couple represents a wide range of permanent thermocouples to be useful to many industries. Mi Couple is produced by : Fykays Engineering Pvt. Ltd. Leaders in Advanced Pyrometry.

On the lop, at the bottom and the walla throughout the arduous path to the control apparatus. Nil Couple and Micab combination of Thermocouple technology is assiduously developed for super fast and accurate temperature measurement from vital spots considered inaccessible so far, as the high temperatures and hitherto undiscovered materials of construction precluded precise probe. It now facilitates rigid quality control denied thus far to the quality conscious decision makers. While helping to improve quality Mi Couple enables closer control on fuel costs. Its contribution to Industrial Safety is a very important consideration in its favour.

Mi Couple is imbedded at the critical process paint to catch the process temperature and transmit the signal to the control apparatus through Mi Cab. ft thus simplifies and hastens decision making for Quality, Economy and Safety. Whereas Mi Couple describes the Mineral insulated thermocouples, Mi Cab describes the Mineral insulated cables that truthfully complement the relay function of Mi Couple through a little less hostile environment.

Mi Cab is the most reliable complement to Mi Couple because it shares its super fast signal transmission efficiency and resistance to the varying temperature zones of the traversing regions and also to static interferences through its exposed path. Mi Couple is made available in many versions, to serve varied industries. Whereas, the Nuclear, Aircraft, special steels, Ferro-Alloys and their like attract the Costlier versions; less exacting conditions in Dairies, Power stations, Pharmaceuticals may opt for the economic variety suited to their respective plants & processes.

Depending on the specifications of each Industrial Process or Product Fykays offer a wide choice for Mi Couple - Mi Cab ingredients.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.