CHIRAG TECHNO

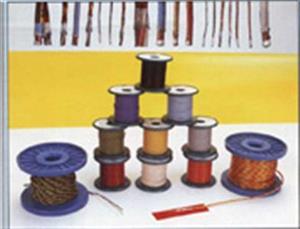

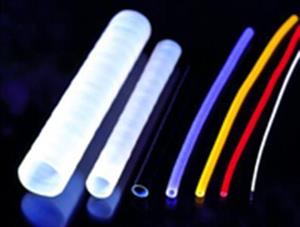

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CHIRAG TECHNO

Cast Nylon Rods Sheets And Pipes

CAST NYLON is generally superior to extruded Nylon-6.Since it is made by direct polymerization of caprolactam, the polymer has never been melted and thus has been subjected to any thermal degradation. In addition, its molecular weight (up to 10,00,000) is several fold higher than molecular weight of extruded nylon6(30,000). Since physical properties of Thermoplastics improve with increasing molecular weight it has Higher tensile and compressive strength, Greater hardness and modulus of elasticity, Higher wear resistance, Lower distortion at Higher temperatures, Lower moisture, Better dimensional stability, Better resistance to solvents than Extruded Nylon 6.Thus for Bearings, Gears and Structural applications. CAST NYLON is the result of a new echnology in Plastics, which makes available to you any shape or size. No longer are you restricted to the smaller size made by extrusion or injection molding methods. Any type of heavy component is now within your reach. The casting process upgrades the Nylon 66 but with lower moistureabsorption and improved strength, it enables production of stress-free stock shapes of almost unlimited size.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.