Products & Services

Fluidized Spray Dryer

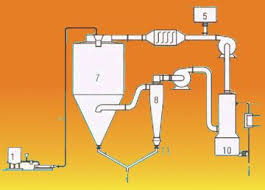

Single stage spray dryers offer particle sizes of dried material from 50-250 microns. For producing large particles Fluidized Spray Dryers are employed. The atomization of the feed solution is done to produce large droplets and the drying in the first stage is done keeping the moisture content of the powder relatively high. The moist powder is dried in the integrated fluid bed system at the bottom of the drying chamber using hit air, and in the process, agglomeration of fines to larger particles takes place. The absolute fines are carried with the exhaust air leaving the drying chamber to be collected in the cyclone and further recalculated to the drying chamber. Tertiary drying systems comprise of employing additional external drying system to further increase the particle size. Shown in the layout is one of such system incorporating a fluidized spray dryer with vibratory fluid bed drier.

Closed Loop Spray Dryer

These are dryers used for drying the product in solvent base, by spraying the solution or slurries in a nitrogen atmosphere and recovering both the product and the solvent. The drying system can be equipped with fire detection, extinguishing and explosion suppressants. Such systems are ideal for handling solvents, heat sensitive products, prevent oxidation of dried product, and also provide aseptic condition.

Spin Flash Dryers

A spin flash dryer produces powder from feed, which is viscous or gelatinous in nature, paste or filter cake. The two step process involves disintegration of the feed and drying of the disintegrated feed. Depending upon the nature of the feed material, conventional arm design could be used for crystalline, non-sticky material or Acmefil's specially engineered rotating spin design disintegrator could be used to handle sticky and gelatinous materials.

Flash Dryers

Drying process is accomplished by contacting the powder with hot air travelling at high velocity. The heat is used for drying and the air pneumatically conveys the powder for separation in a cyclone or a bag filter. A product classifier ensures only dry powder leaving the drying chamber.

Forced Circulation Evaporator

Depending on the liquid characteristics to be concentrated, its temperature sensitivity, thermal degradation properties etc different types of evaporators have been designed and are used for variety of applications in different industries. Single stage systems are employed, where the vapour energy of one stage is used as the heating media for the next stage. Further efficiency increase is obtained by using Thermal Vapour Recompression system or Mechanical Vapour Recompression system.

Natural Circulation Evaporator

Description / Specification of Natural Circulation Evaporator

We are involved in offering a wide range of Natural Circulation Evaporator to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Natural Circulation Evaporator. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Fluid Bed Granulator Cum Coater

ACMEFIL Fluid Bed processing includes Drying as well as granulation, agglomeration and coating of particulate materials.

It is designed to uniform drying of the material at low temperature and is ideal for a wide range of both heat sensitive and non-heat sensitive prodcts for low moist powder.

Vibratory Fluid Bed Dryer Continuous Type

Description / Specification of Vibratory Fluid Bed Dryer Continuous Type

We are involved in offering a wide range of Vibratory Fluid Bed Dryer Continuous Type to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Vibratory Fluid Bed Dryer Continuous Type. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Ultra Filtration System And Membrane System

Membrane technology is the latest and most advanced separation technologies available and used today. The main advantage of membrane technology is, it brings separation without the use of expensive chemicals, minimal unavailable power, no thermal energy requirement and uses the least floor space for said application and proceeds in well defined process conditions

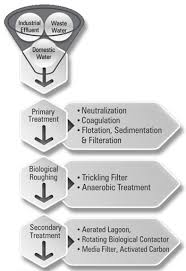

Zero Effluent Discharge System

Description / Specification of Zero Effluent Discharge System

We are involved in offering a wide range of Zero Effluent Discharge System to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Zero Effluent Discharge System. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Bag Filter

Description / Specification of Bag Filter

We are involved in offering a wide range of Bag Filter to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Bag Filter. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design